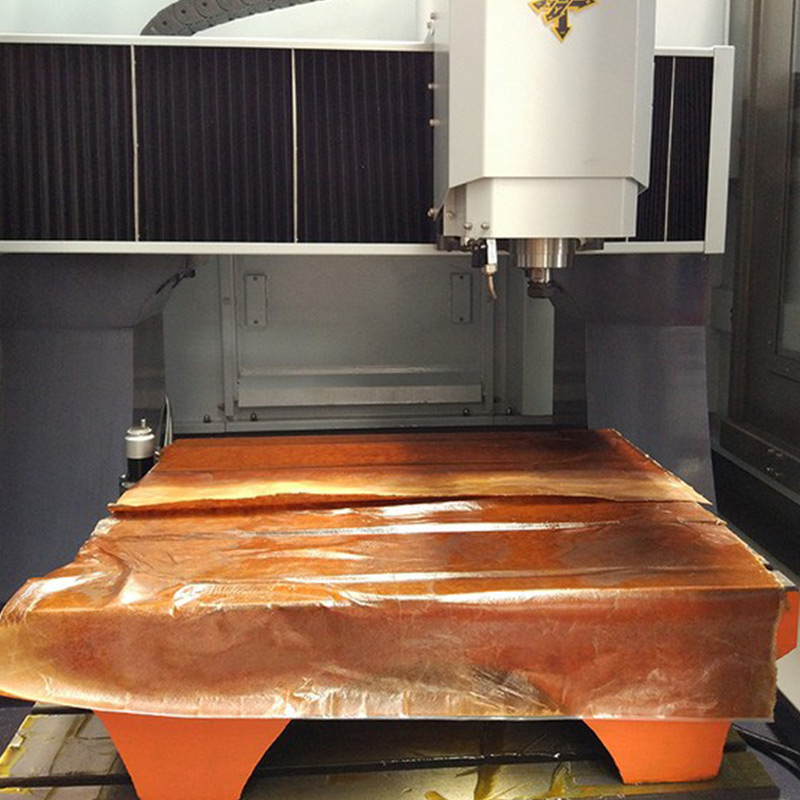

In the global footwear market, the demand for high-precision and high-efficiency production equipment is on the rise. As a result, an increasing number of shoe mold manufacturers are turning to five-axis CNC milling machines to enhance their production capabilities and product quality. This article delves into how shoe mold manufacturing enterprises can scientifically select CNC machining solutions for mass production, with a focus on the core performance indicators of five-axis CNC milling machines.

When it comes to shoe mold manufacturing, several key performance indicators of five-axis CNC milling machines play a crucial role. The spindle speed is one of the most important factors. A higher spindle speed, typically ranging from 10,000 to 24,000 RPM, allows for faster cutting and better surface finish. For example, in a leading shoe mold factory in China, by using a five-axis CNC milling machine with a spindle speed of 20,000 RPM, they were able to reduce the machining time for a complex shoe mold by 30% compared to traditional machines.

Another vital indicator is the positioning accuracy. High positioning accuracy, usually within ±0.005mm, ensures the precision of the shoe mold. In a Southeast Asian shoe mold enterprise, after upgrading to a five-axis CNC milling machine with high positioning accuracy, the rejection rate of shoe molds decreased from 5% to less than 1%.

The tool change speed also significantly impacts production efficiency. A fast tool change speed, which can be as short as 1-2 seconds, reduces the non-cutting time. In a Russian shoe mold factory, by adopting a five-axis CNC milling machine with a quick tool change system, they increased the overall production efficiency by 20%.

Moreover, the compatibility and intelligence level of the control system are essential. A modern control system can support advanced programming and automation functions, enabling seamless integration with other production equipment. In a Middle Eastern shoe mold manufacturing company, the use of a five-axis CNC milling machine with a highly compatible control system improved the coordination between different production processes and reduced the overall production cycle by 25%.

In addition to the equipment performance, optimizing the machining processes is also crucial for shoe mold manufacturing. Programming optimization can effectively reduce the idle stroke. By using advanced CAM software, manufacturers can generate more efficient tool paths, which can save up to 15% of the machining time. For example, a shoe mold manufacturer in China optimized their programming and reduced the idle stroke time from 20% to 5%.

Proper tool life management is another important aspect. By analyzing the cutting conditions and tool wear patterns, manufacturers can determine the optimal tool replacement time. This not only ensures the quality of the shoe molds but also reduces the tool cost. In a Southeast Asian factory, through scientific tool life management, they were able to extend the tool life by 30%.

Standardizing the machining templates can also improve production efficiency and consistency. By creating a set of standardized machining templates for different types of shoe molds, manufacturers can reduce the programming time and ensure the quality stability. In a Russian shoe mold enterprise, after implementing the standardized machining templates, the production efficiency increased by 18%.

Let's take a look at some real-world application cases. A shoe mold manufacturing company in China was facing challenges in meeting the high-precision requirements of their international customers. After replacing their old machines with five-axis CNC milling machines, they were able to improve the surface finish of their shoe molds from Ra 0.8μm to Ra 0.4μm, which significantly enhanced their competitiveness in the global market.

In a Southeast Asian shoe mold factory, they were struggling with low production efficiency and high labor costs. By adopting a five-axis CNC milling machine and optimizing the machining processes, they were able to reduce the labor cost by 40% and increase the production capacity by 50%.

In a Middle Eastern shoe mold enterprise, they were having difficulties in handling complex shoe mold designs. With the help of a five-axis CNC milling machine with advanced control system and programming optimization, they were able to successfully produce complex shoe molds that were previously impossible to manufacture, which opened up new market opportunities for them.

As the global footwear market continues to evolve, shoe mold manufacturing enterprises need to embrace advanced technologies and optimize their production processes. Five-axis CNC milling machines offer a powerful solution for enhancing production efficiency, product quality, and competitiveness. Whether you are a shoe mold manufacturer in China, Southeast Asia, the Middle East, or Russia, the information and strategies provided in this article can help you make informed decisions and achieve a smooth transition from trial production to large-scale production.

Ready to take your shoe mold manufacturing to the next level? Explore our five-axis CNC milling machines and start your journey towards efficient, flexible, and intelligent manufacturing today!