In the aerospace industry, the demand for high precision and efficiency in part machining has been continuously increasing. As a result, five-axis vertical machining centers are gradually becoming the preferred choice to replace traditional three-axis equipment. This article delves into the advantages of five-axis vertical machining centers in complex geometry processing, especially their performance in graphite material processing, and explores how they help enterprises achieve dual improvements in processing quality and production efficiency.

The aerospace and related high-precision manufacturing industries have strict requirements for machining equipment. They need equipment that can handle complex geometric shapes with high precision and efficiency. Traditional three-axis machines often face limitations in these aspects, such as the need for multiple setups and longer processing times.

When it comes to complex geometric structures, five-axis vertical machining centers have significant advantages over three-axis machines. Three-axis machines usually require multiple setups to process different surfaces of a part, which not only increases the processing time but also may introduce errors. In contrast, five-axis machines can process multiple surfaces in a single setup, reducing the number of setups and optimizing the processing path. For example, in some complex aerospace parts, the use of a five-axis machine can reduce the setup time by up to 50% and improve the processing efficiency by 30%.

Graphite materials are widely used in the aerospace industry due to their excellent properties. Five-axis vertical machining centers show unique technical advantages in graphite material processing. They have high repeat positioning accuracy, which can ensure consistent quality in mass production. The thermal stability of these machines is also remarkable, which is crucial for maintaining precision during long - term processing. In addition, they are well - adapted to thin - walled parts, which are common in graphite components used in aerospace. For instance, the repeat positioning accuracy of a high - end five - axis vertical machining center can reach ±0.005mm, ensuring high - quality graphite part production.

Let's take a real - world customer case as an example. A well - known aerospace parts manufacturer upgraded from a three - axis machine to a five - axis vertical machining center. After the upgrade, the yield rate of their products increased from 85% to 95%. At the same time, the tool change time was shortened by 40%, which significantly improved the overall production efficiency. These data clearly show the practical value of five - axis vertical machining centers.

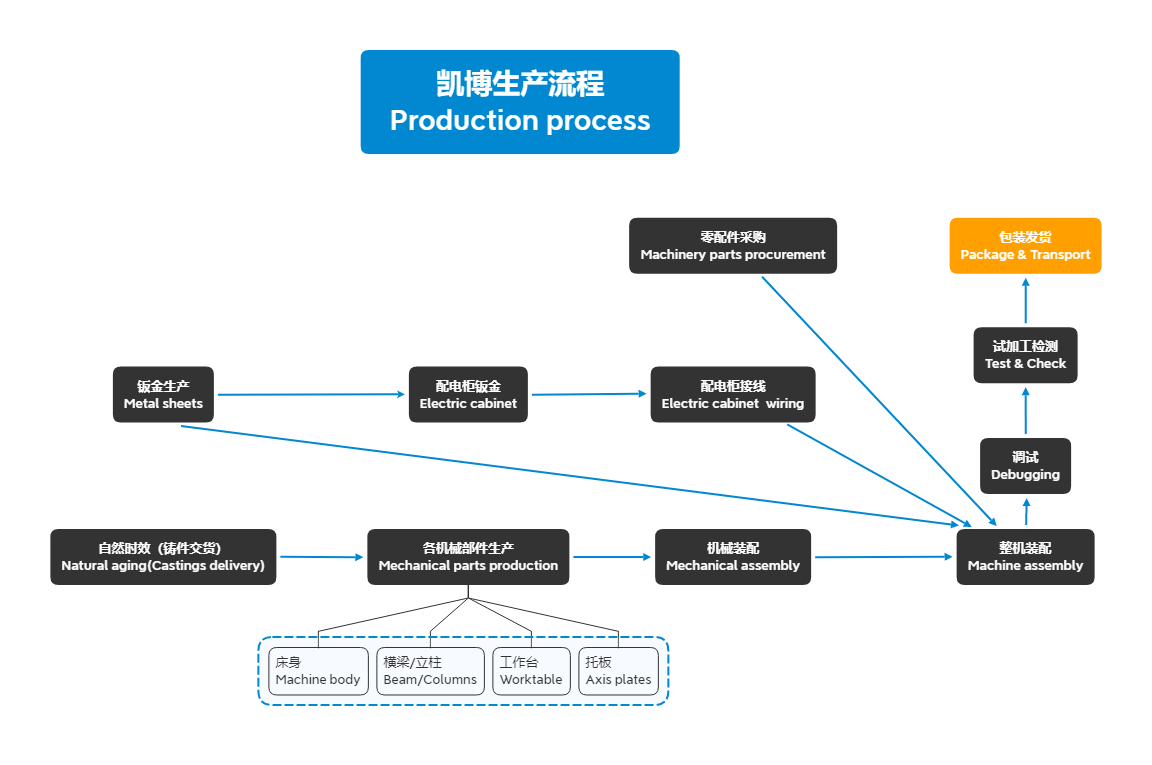

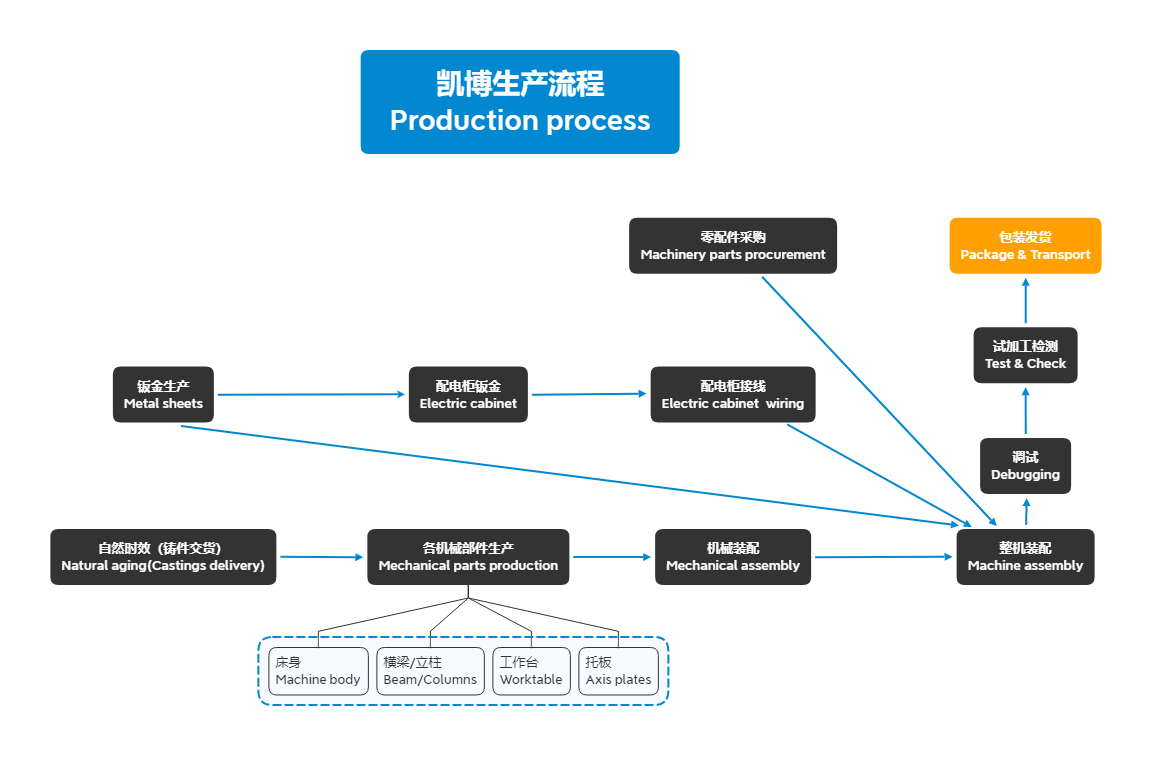

To simplify the understanding of professional technologies, technical demonstration and visualization tools are often used. These tools can help engineering decision - makers better understand the working principles and advantages of five - axis vertical machining centers. By presenting complex technical information in an intuitive way, they make it easier for users to evaluate the suitability of these machines for their production needs.

For enterprises in the aerospace and related industries, upgrading to five - axis vertical machining centers is a strategic decision to meet future challenges. This upgrade can not only improve processing quality but also enhance production efficiency, which is crucial for maintaining competitiveness in the market. By choosing the right five - axis machine, enterprises can better adapt to the changing requirements of the industry.

Are you ready to take your aerospace and graphite material processing to the next level? Discover the core value of our five - axis vertical machining centers and transform your production process. Click here to learn more!