The rise of the footwear cluster in Southeast Asia has brought about a significant surge in multi - variety and small - batch orders. This new market dynamic has put pressure on shoe mold manufacturing enterprises to seek more efficient and flexible CNC machining solutions. With the increasing complexity of orders, the demand for equipment that can quickly respond to different product requirements has become more urgent.

Southeast Asian footwear manufacturers are now dealing with a wide range of shoe styles and designs, which means shoe mold makers need to be able to produce various types of molds in a short time. For example, a factory might receive orders for sports shoes, casual shoes, and high - heeled shoes all in one month. To meet these diverse needs, flexible manufacturing equipment is no longer a luxury but a necessity.

Five - axis CNC milling machines have emerged as a game - changer in the shoe mold manufacturing industry. Their core performance indicators, such as spindle speed, positioning accuracy, tool - changing speed, and control system compatibility, play a crucial role in determining the production efficiency.

Let's take a look at some data. A high - end five - axis CNC milling machine with a spindle speed of over 10,000 RPM can significantly reduce the machining time compared to a machine with a lower spindle speed. Positioning accuracy is also vital. A machine with an accuracy of ±0.005mm can ensure the precision of shoe molds, which is essential for the quality of the final shoes. The tool - changing speed can affect the overall production cycle. A machine that can change tools within 3 seconds can improve the production efficiency by up to 20% compared to a machine with a slower tool - changing speed.

Different configurations of five - axis CNC milling machines can have a significant impact on the delivery efficiency of multi - variety orders. For instance, a machine with a more advanced control system can better handle complex programming and adapt to different production requirements. A machine with better compatibility with various cutting tools can also improve the production flexibility.

We conducted a comparison test on two different five - axis CNC milling machines. Machine A with a basic configuration took an average of 10 hours to complete a set of multi - variety shoe molds, while Machine B with a high - end configuration only took 7 hours. This shows that the right configuration can significantly improve the production efficiency and order delivery speed.

In a real - world factory, process optimization strategies are crucial for improving production efficiency. For example, by reducing the empty stroke of the machine, the production time can be shortened. One factory was able to reduce the empty stroke by 30% through careful programming, which led to a 15% increase in overall production efficiency.

Another important strategy is tool life management. By properly allocating the tool life, the factory can reduce the frequency of tool changes and improve the production continuity. A factory case showed that by using a tool life management system, the tool change frequency was reduced by 40%, and the production downtime was significantly decreased.

"In our factory, we found that by optimizing the programming and tool life management, we were able to increase the production output by 25% in just three months," said a factory manager.

Standardized processing templates can significantly reduce the operation threshold and improve the consistency of production. By using standardized templates, even inexperienced operators can quickly start working on the machine. These templates also ensure that each mold is produced with the same high - quality standards.

A factory introduced standardized processing templates and found that the defect rate was reduced from 5% to 1%. This not only improved the product quality but also saved a lot of production costs.

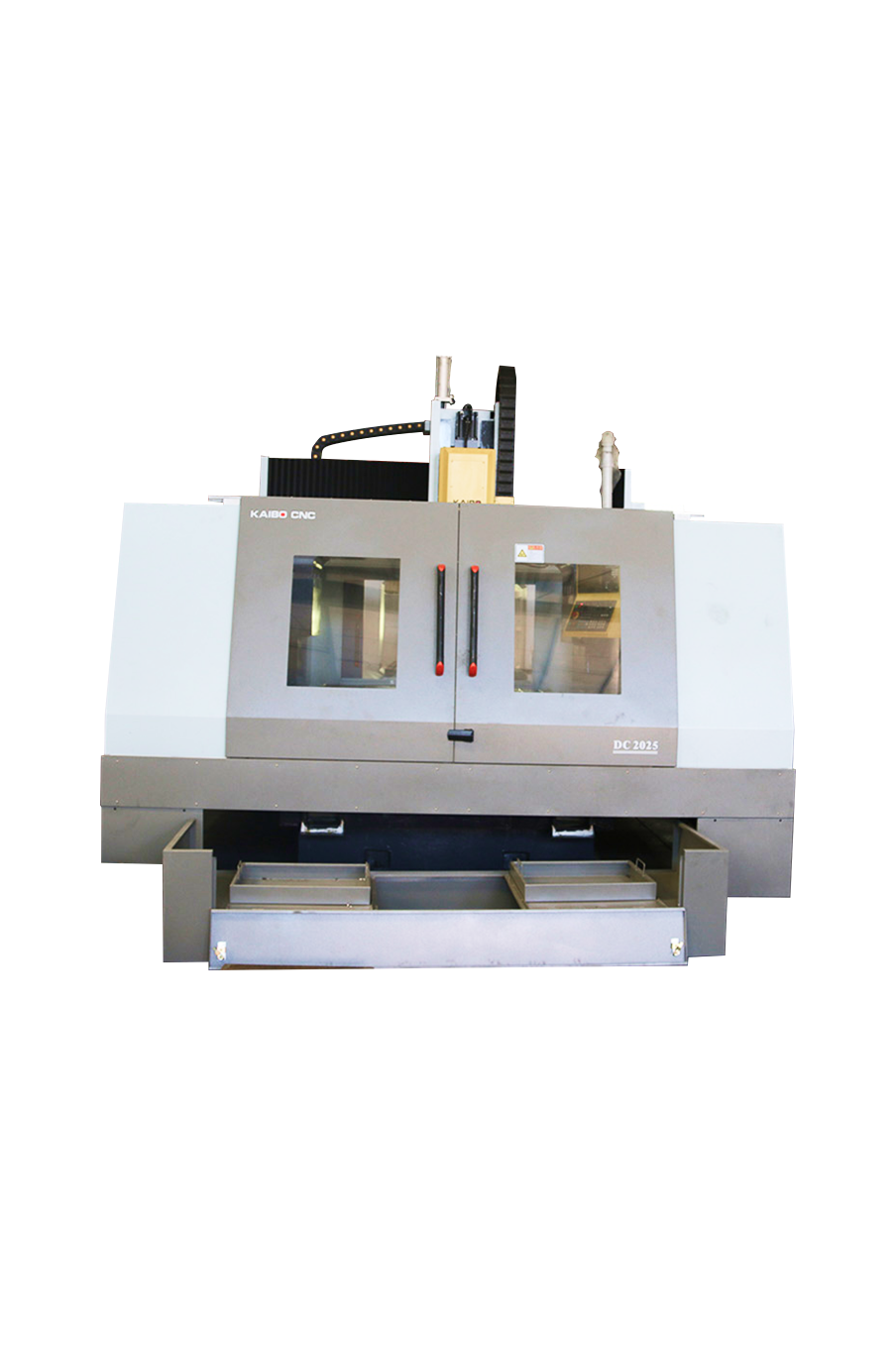

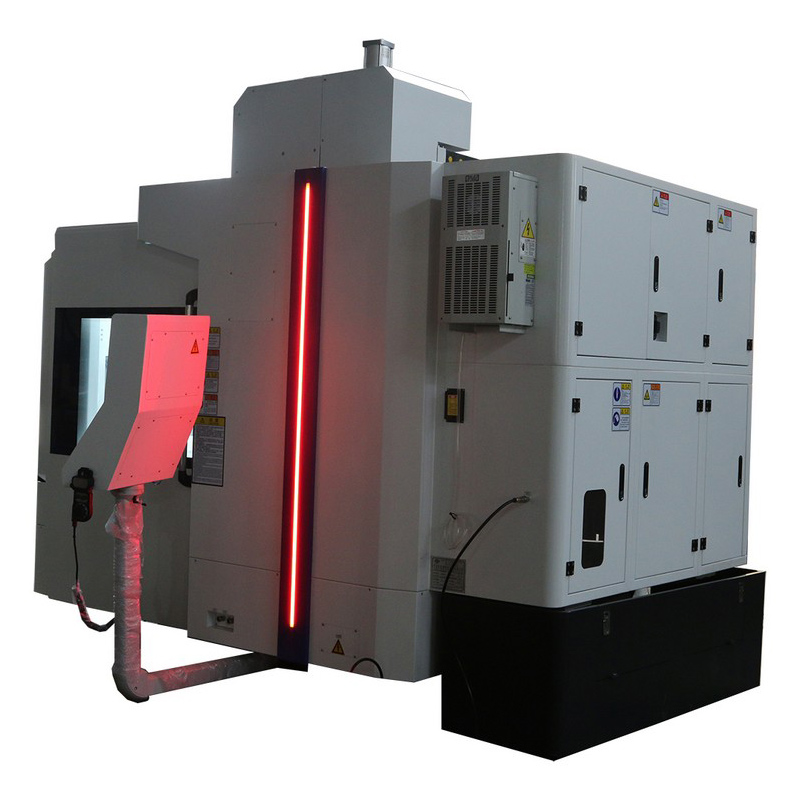

One of the challenges for shoe mold manufacturers is to make a smooth transition from prototype production to mass production. A good five - axis CNC milling machine should be able to handle both single - piece trial production and large - scale production. For example, the Kaibo DC6060A five - axis sole mold milling machine is designed to provide a seamless transition.

In addition, proper operation and maintenance support are essential for the long - term performance of the machine. A machine that comes with 24/7 technical support and regular maintenance services can ensure the continuous operation of the production line.

If you are looking for a reliable solution to improve your shoe mold production efficiency and flexibility, the Kaibo DC6060A five - axis sole mold milling machine is the answer. 立即了解凯博DC6060A如何助力您的产能跃升 (Immediately learn how Kaibo DC6060A can boost your production capacity).