Rapid Establishment of Standardized Five-Axis Programming Workflow to Shorten International Trial Production Cycles

This article provides a comprehensive guide to quickly building a standardized five-axis programming workflow. It delves into the core logic of five-axis simultaneous programming, covering coordinate system transformations, tool path planning, interference checks, and simulation verification. Special emphasis is placed on machining challenges posed by non-metallic materials like graphite, offering practical strategies to prevent thermal deformation and control cutting force fluctuations. Through real-world case studies such as impellers and mold cavities, you will learn how to create an efficient and reusable programming standard that significantly reduces international customers' trial production lead times and improves first-time molding success rates.

How to Quickly Establish a Standardized 5-Axis Programming Process to Shorten International Client Trial Production Cycles

In today's competitive manufacturing landscape, shaving days or even hours off your trial production cycles can mean winning or losing international clients. If you're working with complex parts and challenging materials like graphite, mastering a standardized 5-axis programming process is essential for boosting efficiency and first-time success rates.

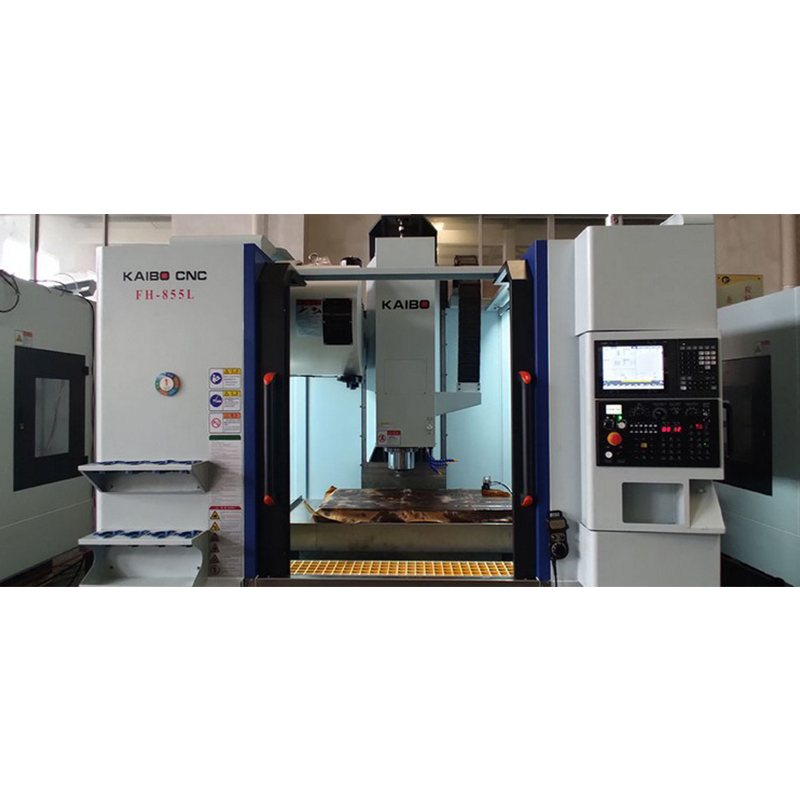

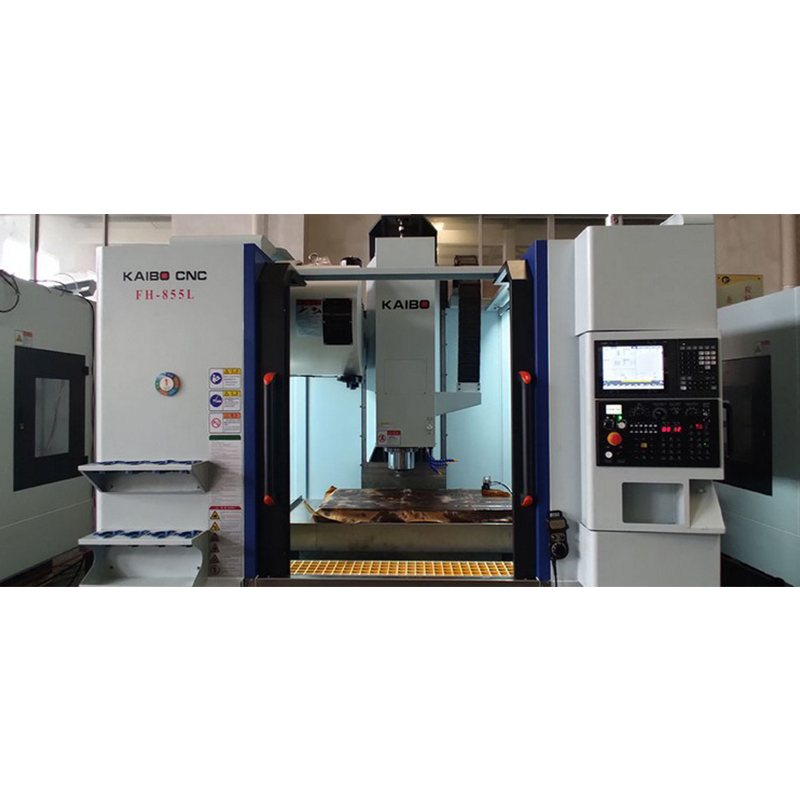

Understanding the Core Logic of 5-Axis Simultaneous Programming

At the heart of effective 5-axis CNC programming is an adept handling of coordinate system transformations, toolpath planning, collision checking, and simulation verification. You begin by defining the workpiece coordinate system aligned to the raw material or fixture, then transition through multiple spatial rotations to optimize tool angles.

Advanced CAM software facilitates this by providing Real-Time Collision Prevention (RTCP), which dynamically adjusts the tool center point considering the rotary axes' movement — a must-have feature in complex five-axis machining centers to avoid interference and achieve high precision.

Key Steps for Creating a Repeatable and Efficient Programming Workflow

- Consistent Coordinate Setup: Always align your coordinate system with part features to minimize rework. Use fixture offsets programmed into your machine to reference repeatability.

- Reliable Tool Path Strategies: Select machining strategies suitable for 5-axis movements—such as swarf cutting along curved surfaces or contour finishing—to maintain smooth transitions and reduce tool load.

- Collision and Interference Simulation: Before running the actual program, thoroughly simulate rotary axis motions and tool-holder clearances in your CAM environment. This step catches costly errors early.

- Validation Through Trial Runs: Conduct dry runs or trial cuts on representative material to confirm the programmed paths and refine feeds and speeds.

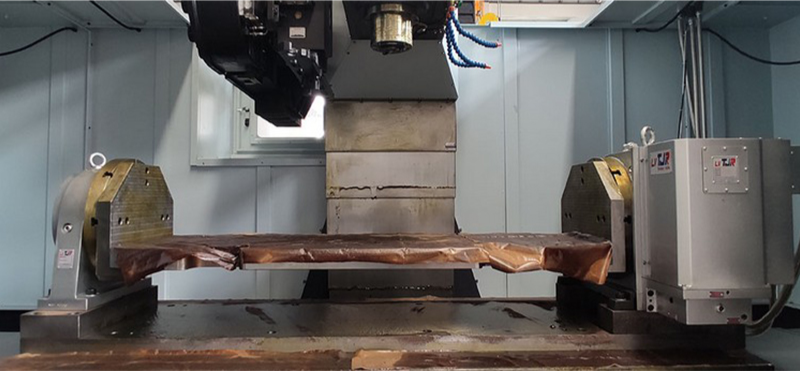

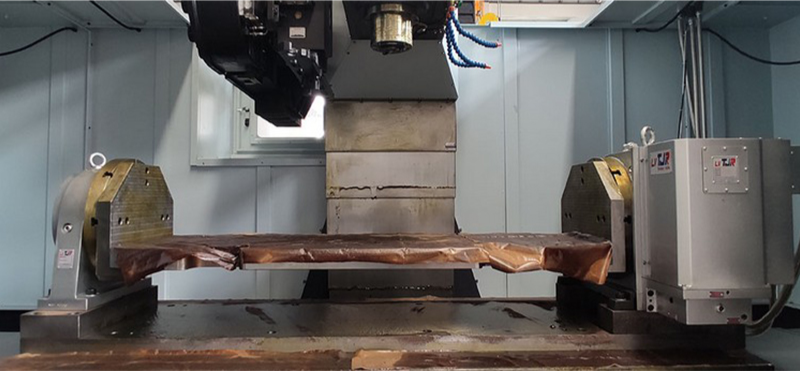

Addressing Programming Challenges When Machining Graphite and Other Non-metallic Materials

Graphite machining is notoriously tricky due to its low thermal conductivity and powdery chip generation, which can cause thermal deformation and unpredictable cutting forces. To manage these, incorporate these techniques into your strategy:

- Heat Deformation Control: Minimize cutting depth per pass and reduce spindle speeds to lower the heat generated during milling.

- Stable Cutting Force Management: Adopt oscillating or trochoidal machining paths to prevent sudden force spikes that damage the surface finish.

- Regular Tool Changes and Dust Evacuation: Maintain sharp tools and ensure efficiently evacuated graphite dust to avoid tool wear and surface degradation.

Case Studies: Practical Applications in Impeller and Mold Cavity Machining

Programming intricately curved parts such as impeller blades and mold cavities demonstrates the power of a streamlined 5-axis approach.

By adopting synchronized 5-axis tool tilt aligned with blade geometry, you reduce step-over marks and maintain consistent tool engagement. For mold cavities, employing adaptive roughing with finishing passes mapped to surface curvature ensures zero undercuts and smooth finishes.

Avoiding Common Errors Across Popular CAM Software

| Software |

Typical Errors |

Best Practices |

| Mastercam |

Ignoring rotary axis limits causing collisions |

Enable axis limits and use simulation Wizards |

| Siemens NX CAM |

Incorrect post-processor settings leading to axis misalignment |

Match post-processor precisely to machine model |

| CATIA |

Overlooking tool holder collisions in complex geometries |

Comprehensive tool assemblies and dynamic collision checks |

Standardize your CAM setups, post-processing, and simulation routines to ensure every programmer is operating from the same efficient playbook.

Frequently Asked Questions

-

Q1: How much can a standardized 5-axis programming process reduce trial production time?

-

With optimized workflows and validated templates, you can reduce trial production lead time by 30% to 50%, crucial for fast international deliveries.

-

Q2: What are essential CAM features for 5-axis graphite machining?

-

Look for RTCP support, collision avoidance tools, advanced toolpath strategies like trochoidal cutting, and robust simulation capabilities.

-

Q3: How can I ensure program portability between different 5-axis machines?

-

Use machine-specific post-processors and maintain a consistent coordinate zero and fixture setting protocol across shops.

Interactive Your Turn: What Challenges Do You Face in Five-Axis Programming?

Understanding your specific hurdles can help tailor solutions. Consider:

- Are thermal deformations consistent issues with your materials?

- Do you struggle with CAM software compatibility or post-processing?

- Is your team aligned on a documented programming standard?

Reflect on these points to unlock improvements in your process.