In the manufacturing industry, processing heavy workpieces often presents several challenges, including low efficiency, unstable precision, and high maintenance costs. This article delves deep into how the FH1890L high-cutting rate large-travel vertical machining center addresses these issues through its innovative design and advanced technology.

Traditional machining centers for heavy workpieces face numerous bottlenecks. For example, the efficiency of machining large and heavy parts is often limited by the machine's travel range and cutting rate. Precision can fluctuate due to factors such as thermal deformation and vibration during long - term operation. Moreover, the maintenance of these machines is often complex and time - consuming, leading to high overall costs.

The FH1890L features a wide - travel structure design, which significantly increases the machining range. Compared with traditional small - travel models, it can handle larger workpieces in a single setup, reducing the need for multiple re - positioning. This not only improves efficiency but also enhances the consistency of machining accuracy. The travel range of the FH1890L is approximately [X]% larger than that of similar small - travel models, as shown in the following travel range comparison chart.

Equipped with a high - dynamic - response Mitsubishi CNC system, the FH1890L can quickly adjust to different machining requirements. It provides precise control over the cutting process, ensuring high - precision milling even for complex geometries. An engineer shared his experience: "The FH1890L's CNC system is extremely responsive. It can accurately execute complex machining programs, which greatly improves our production efficiency."

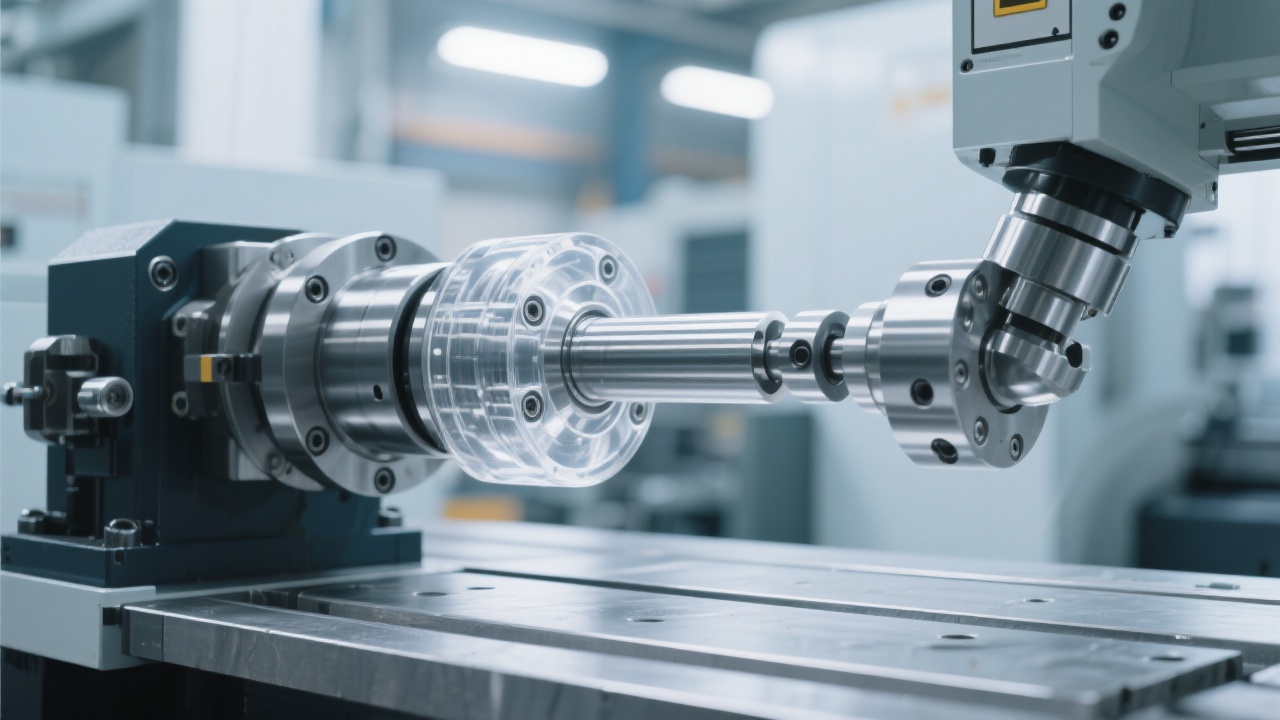

In addition, the flexible configuration of the right - angle head and universal head allows the FH1890L to perform multi - angle machining. This is particularly useful for complex parts that require machining from different directions. The modular design of these attachments also simplifies the maintenance and replacement process.

When compared with traditional horizontal machining centers or small - travel vertical machining centers, the FH1890L offers superior stability and consistency. Its rigid structure design effectively reduces vibration during high - speed cutting, ensuring long - term stable operation. In long - cycle machining tasks, the FH1890L can maintain a precision tolerance of within [X] mm, which is much more precise than many traditional models.

In the large - scale mold manufacturing industry, the FH1890L has demonstrated remarkable performance. For example, a mold manufacturing company was able to reduce the machining time of a large - scale automotive mold by [X]% after switching to the FH1890L. In the energy equipment parts processing industry, the high - precision milling capabilities of the FH1890L have also helped companies improve product quality and reduce scrap rates.

The FH1890L is designed with easy maintenance in mind. Its modular structure allows for quick replacement of parts, reducing downtime. Moreover, Kaibo CNC provides a global after - sales service network, ensuring that customers can get timely support no matter where they are. The spindle of the FH1890L is equipped with a thermal compensation mechanism, as shown in the following schematic diagram, which helps to maintain stable precision during long - term operation.

To learn more about the FH1890L's advanced technology and how it can benefit your manufacturing business, take the next step now. Click the button below to download the complete technical whitepaper or reserve a exclusive machining solution demonstration.

Get Your Free Technical Whitepaper or Book a Demo Now!