In today’s competitive footwear market, flexibility and precision are no longer optional—they’re essential. For shoe mold manufacturers transitioning from prototyping to high-volume production, choosing the right 5-axis CNC milling machine can mean the difference between delayed orders and on-time delivery with consistent quality.

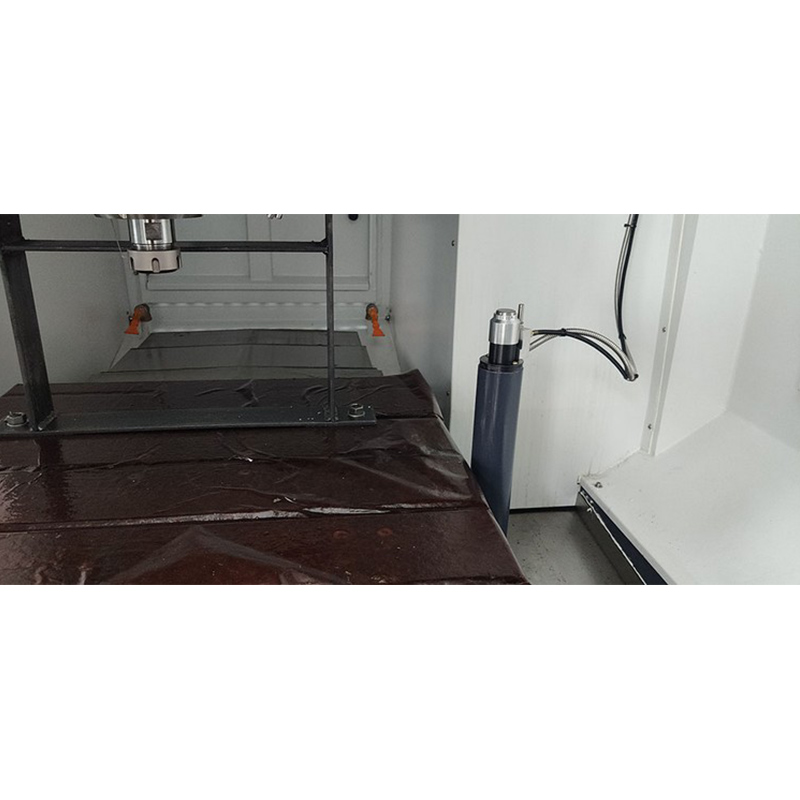

Let’s cut through the jargon. When evaluating machines like the DC6060A Shoe Sole Mold CNC Milling Machine from Ningbo Kaibo CNC Machinery Co., Ltd., focus on four core indicators:

| Parameter | Industry Standard | DC6060A Benchmark |

|---|---|---|

| Max Spindle Speed | 12,000 RPM | 15,000 RPM |

| Positioning Accuracy | ±0.005 mm | ±0.003 mm |

| Tool Change Time | 2.5 seconds | 1.8 seconds |

| Control System Compatibility | Standard G-code | Supports Siemens, Fanuc, & Custom PLC |

These specs aren’t just numbers—they translate directly into faster changeovers, fewer rejects, and smoother transitions from single-piece trials to full-scale batches. One factory in Guangdong reported a 37% reduction in setup time after switching to the DC6060A, allowing them to handle up to 12 different shoe sole models per week without sacrificing quality.

The real test of any CNC solution is how well it supports your workflow—not just its raw power. At Kaibo, we’ve seen clients use the DC6060A to standardize toolpaths across multiple mold families, reducing programming errors by over 60%. By implementing a structured cutting template library, shops can reuse proven strategies instead of starting from scratch each time.

And let’s talk about tool life—a hidden cost driver. With optimized spindle speeds and intelligent feed rate adjustments, users report an average increase of 22% in tool longevity compared to older 3-axis systems. That’s not just savings—it’s less downtime, more predictable lead times, and happier customers.

Whether you're scaling up from 10 to 100 units per month or managing complex seasonal demand cycles, the DC6060A gives you the agility to respond—without compromising on finish or consistency.

Get a personalized demo of the DC6060A and see how it fits your current processes—and your growth plans.

See How the DC6060A Can Boost Your Flexibility Today