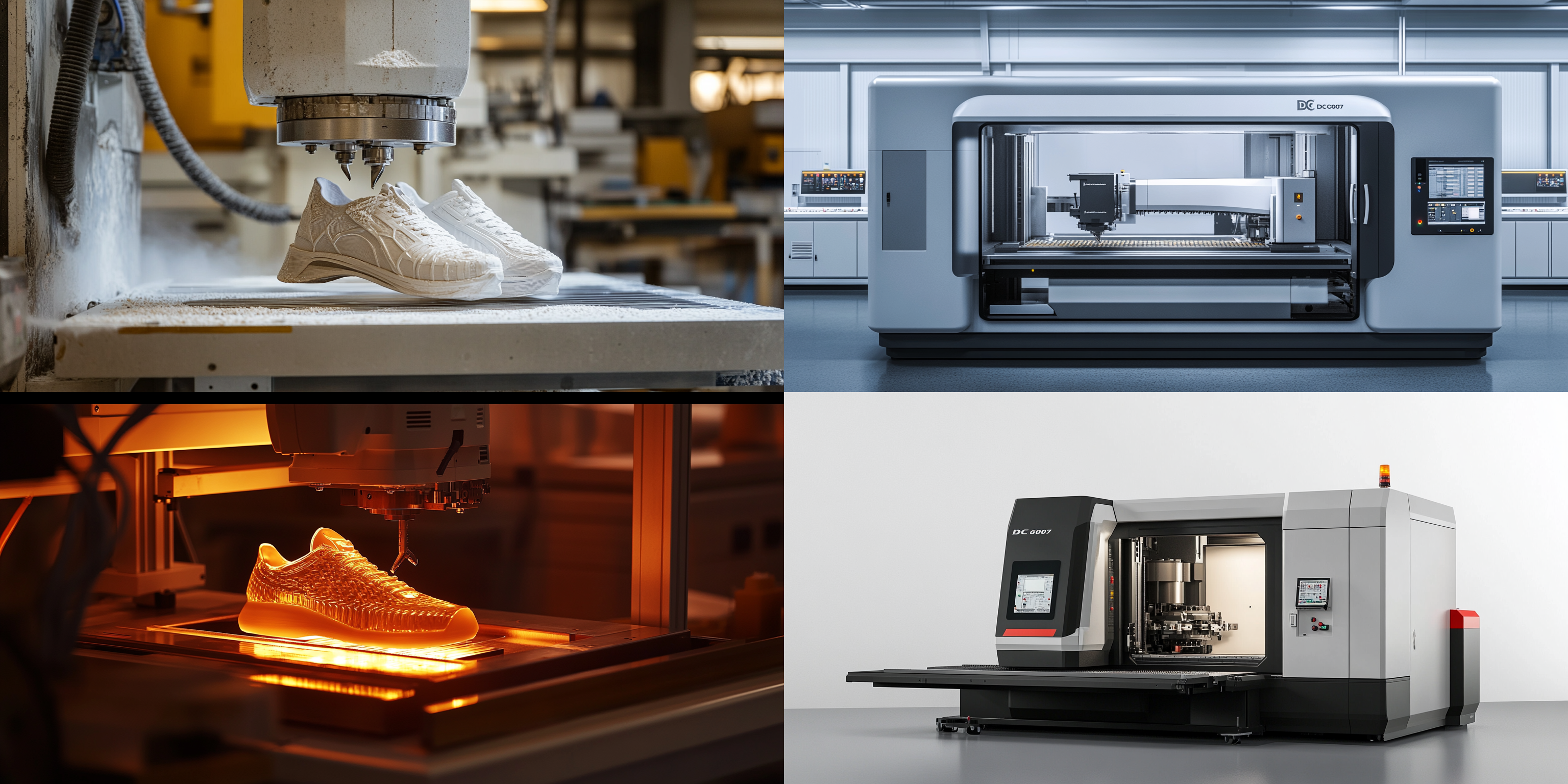

In the shoe mold manufacturing industry, frequent tool changes often lead to production interruptions, significantly reducing equipment utilization and production efficiency. As a global trade and B2B marketing expert with over 20 years of international market experience, I've witnessed firsthand the challenges faced by shoe mold enterprises. Today, I'll share some valuable insights on optimizing the tool change path of shoe mold milling machines based on a real - world case from Ningbo Kaibo CNC.

There are mainly two types of tool magazines commonly used in shoe mold milling machines: drum - type and arm - type. The drum - type tool magazine is simple in structure and relatively low in cost. However, in high - speed and high - load scenarios, it often shows limitations in terms of stability and tool change speed.

In contrast, the arm - type tool magazine has significant advantages. It can achieve faster tool change operations and maintain high stability even under high - speed and high - load conditions. For example, in a high - volume shoe mold production environment, the arm - type tool magazine can reduce the tool change time by about 30% compared to the drum - type tool magazine, greatly improving the continuous operation ability of the equipment.

The ATC (Automatic Tool Changer) tool change process mainly consists of three steps: tool recognition, path planning, and execution. Let's take a detailed look at each step:

The first step is to accurately identify the required tool. This requires the system to have a reliable tool identification mechanism, such as using barcodes or RFID tags on the tools. Once the system receives the tool change command, it can quickly and accurately locate the target tool.

After tool recognition, the system needs to plan the optimal tool change path. This involves setting a series of key parameters, such as the movement speed of the tool magazine, the rotation angle of the tool arm, and the distance between the tool and the spindle. By adjusting these parameters, we can ensure that the tool change process is fast and accurate. For example, proper adjustment of the tool arm rotation speed can reduce the tool change time by 20%.

Finally, the system executes the tool change operation according to the planned path. During this process, it is necessary to ensure the accuracy of each movement to avoid tool collisions or misplacements. We can use coordinate calibration methods to improve the accuracy of tool movement. For example, by calibrating the coordinates of the tool magazine and the spindle, we can reduce the positioning error to within ±0.05mm.

Let me share an anonymous customer case to illustrate the effectiveness of these optimization methods. A Southeast Asian shoe factory was facing the problem of long tool change times, which seriously affected their production efficiency. After our technical team's in - depth analysis and optimization of their DC6060A five - axis shoe sole mold milling machine, we successfully reduced the tool change time by 40%. This not only improved the continuous operation ability of the equipment but also increased the unit - time output by about 35%.

Based on the above analysis, we can summarize some reusable tool change path optimization strategies. For example, we can use the shortest path algorithm to plan the tool change path, and regularly calibrate the coordinates of the tool magazine and the spindle to ensure the accuracy of tool movement.

When performing coordinate calibration, we need to follow a certain step - by - step process. First, we need to establish a reference coordinate system, and then measure the coordinates of key points such as the tool magazine and the spindle. Finally, we adjust the system parameters according to the measurement results to achieve accurate positioning.

By optimizing the ATC system of shoe mold milling machines, we can significantly improve the equipment utilization and delivery ability. The reduction of tool change time means that the equipment can operate continuously for a longer time, increasing the unit - time output. At the same time, the improvement of stability and accuracy can also reduce the defective rate of products, improving the overall quality of shoe molds.

We have helped many shoe mold enterprises achieve significant improvements in continuous operation ability. If you are also interested in optimizing your shoe mold milling machine's ATC system, you can click here to get the "Five - Axis Milling Machine ATC Debugging Manual" PDF version, which will help you quickly get started and achieve better production results.