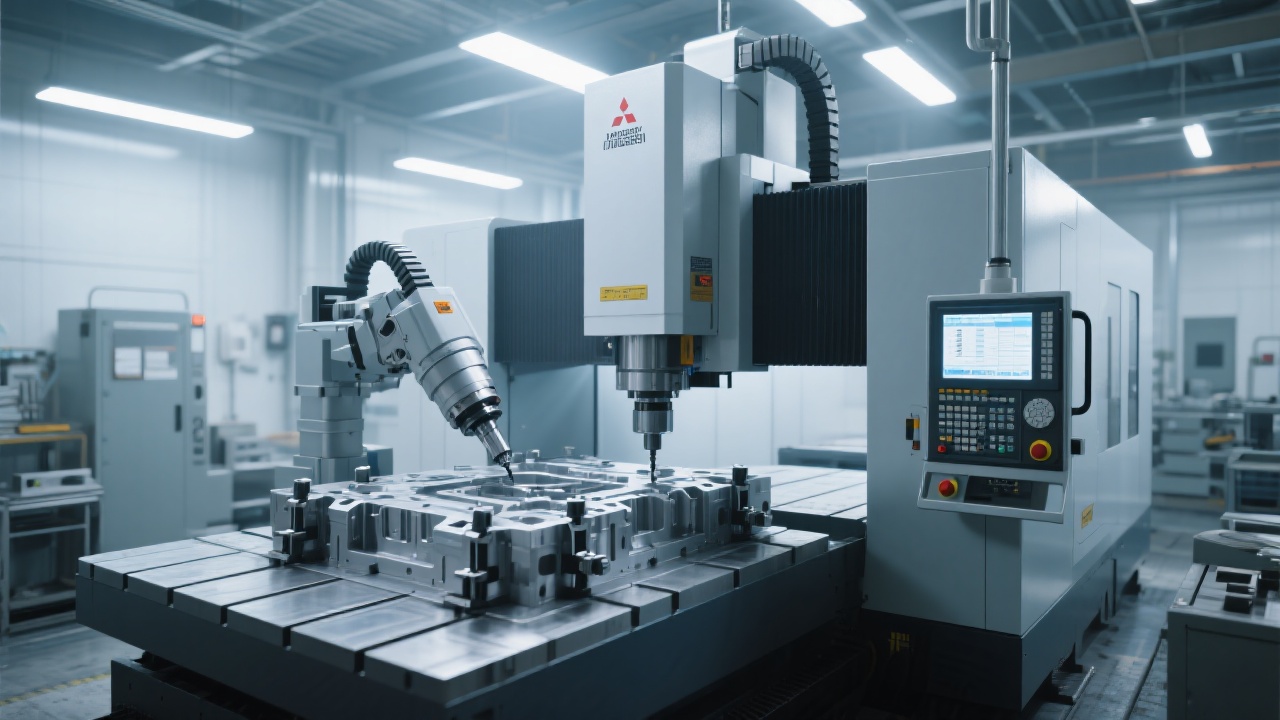

The FH1890L high - cutting - rate large - travel vertical machining center, independently developed by Ningbo Kaibo CNC Machinery Co., Ltd., is specifically designed for graphite and large heavy - duty workpiece processing. It is equipped with a high - dynamic response Mitsubishi CNC system and supports various configurations of right - angle heads, universal heads, and spindle extension rods, significantly enhancing processing flexibility and compatibility with complex processes.

The FH1890L features a rigid structural design. Its robust frame can withstand heavy loads during the machining process. For example, in the processing of large aerospace components, the machine can maintain stable operation even when the cutting force reaches up to 5000 Newtons. This is in contrast to traditional small - travel or horizontal machining centers, which may experience vibrations and instability under such high - load conditions. According to interviews with front - line engineers, the rigid structure of the FH1890L ensures that the machining accuracy can be controlled within ±0.01mm, which is crucial for industries that require high - precision parts such as the mold manufacturing industry.

The integration of the Mitsubishi CNC system is a major highlight of the FH1890L. This high - dynamic response system can quickly adjust the machining parameters according to the real - time cutting situation. In the rough - machining process of large graphite electrodes, the system can increase the cutting speed by up to 30% compared with traditional CNC systems, significantly improving production efficiency. Also, it has excellent compatibility with various tooling configurations, allowing for seamless switching between different machining processes, which is very important for reducing production time and costs.

The FH1890L offers a rich selection of modular accessories, including right - angle heads, universal heads, and spindle extension rods. These accessories can greatly expand the machining capabilities of the machine. For instance, in the energy equipment manufacturing industry, the use of a right - angle head can enable the machine to perform multi - surface machining on large - sized workpieces without re - clamping, which not only improves the machining accuracy but also enhances the processing efficiency. By using these accessories, the processing flexibility of the FH1890L can be increased by approximately 40% compared to machines without such accessory options.

In the mold manufacturing industry, a certain enterprise used the FH1890L to process large - scale automotive molds. Previously, with traditional machining centers, the production cycle of a set of molds was about 30 days, and the reject rate was about 5%. After switching to the FH1890L, the production cycle was shortened to 20 days, and the reject rate was reduced to less than 1%. In the aerospace industry, the FH1890L's high - precision and high - stability machining performance ensures the quality of critical components, meeting the strict requirements of this industry. Similarly, in the energy equipment manufacturing industry, it helps to improve the production efficiency and product quality in the processing of large - scale power generation equipment components.

In addition to its excellent performance, Ningbo Kaibo CNC Machinery Co., Ltd. also provides a global after - sales service system. This system ensures that customers can get timely technical support and maintenance services no matter where they are, which further enhances the attractiveness of the FH1890L for international customers.

If you are a factory equipment procurement manager or a process designer, and you are looking for a high - performance machining center that can improve production efficiency and control costs, the FH1890L is definitely a great choice. Don't miss out on this opportunity to upgrade your production capabilities!

Get the Complete Technical Whitepaper or Schedule an On - site Demo Now!