In the high - end manufacturing industry, the demand for the processing efficiency and precision of heavy workpieces has been constantly increasing. However, heavy workpiece processing faces significant pain points and challenges, especially in terms of efficiency, precision, and equipment maintenance.

Traditional processing methods often result in low efficiency in heavy - load rough processing. The processing precision is difficult to guarantee, especially for large - scale and complex heavy workpieces. Moreover, the maintenance of equipment is complex, with high costs and long downtime, which seriously affects production schedules. For example, in some large - scale mold manufacturing factories, the processing cycle of a large mold can be extended by 20 - 30% due to low - efficiency processing equipment, and the scrap rate caused by inaccurate processing can reach about 5 - 8%.

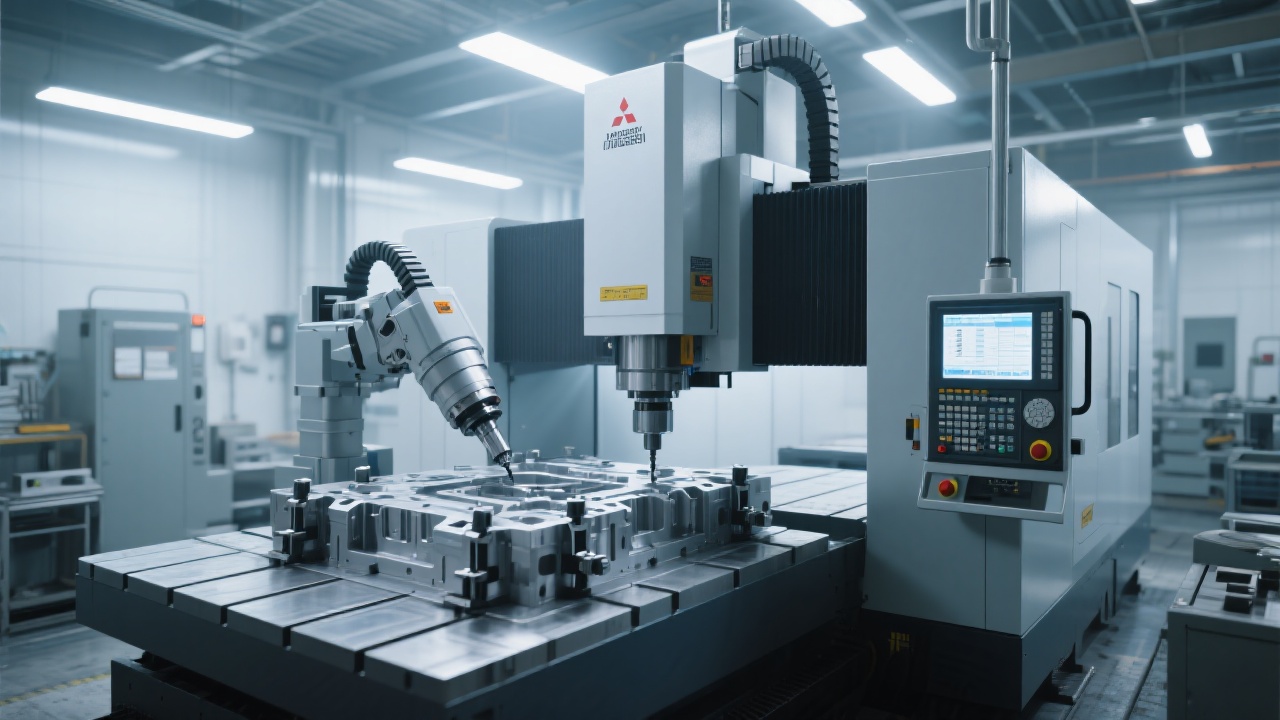

Ningbo Kaibo CNC Machinery Co., Ltd. has independently developed the FH1890L large - stroke vertical machining center, which effectively addresses these issues. Structurally, the FH1890L features high - rigidity design. Its frame is made of high - quality cast iron, with a wall thickness of up to 30 - 40mm, which can effectively resist deformation during heavy - load processing. The advanced Mitsubishi CNC system is integrated into the machine, which has high - speed processing capabilities. The system can achieve a maximum feed rate of 24m/min, greatly improving processing efficiency.

It also offers a variety of modular accessories. For example, different types of tool magazines can be selected according to different processing requirements, with tool storage capacities ranging from 20 to 60. This modular design allows users to customize the machine according to their actual needs, reducing unnecessary costs.

In the mold manufacturing industry, the FH1890L has shown excellent performance. A well - known mold factory in Dongguan used to take about 15 days to process a large - scale automotive mold using traditional equipment. After using the FH1890L, the processing time was reduced to about 10 days, and the surface roughness of the mold was reduced from Ra3.2μm to Ra1.6μm, greatly improving the quality of the mold.

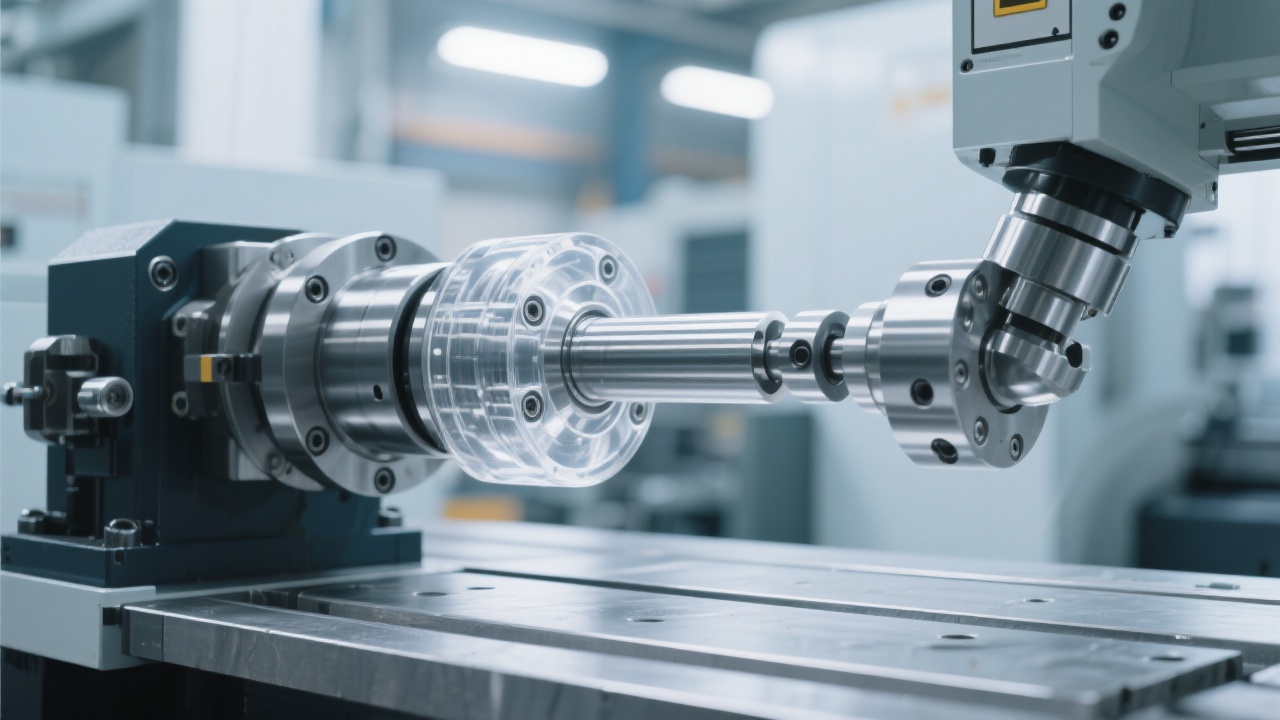

In the aerospace field, the processing of some high - precision parts requires extremely high accuracy. The FH1890L can achieve a positioning accuracy of ±0.005mm and a repeat positioning accuracy of ±0.003mm, which meets the strict requirements of aerospace parts processing. In the energy equipment industry, for the processing of large - scale turbine blades, the FH1890L can complete rough and fine processing in one setup, improving processing efficiency by about 30% compared with traditional methods.

Compared with traditional horizontal and small - stroke machines, the FH1890L has significant advantages. In terms of stability, the large - stroke design of the FH1890L allows it to maintain high - speed and stable operation during long - term processing. In a continuous 7×24 - hour operation test, the traditional small - stroke machine had to stop for maintenance every 3 - 4 days due to overheating and wear, while the FH1890L could operate continuously for more than 15 days without major problems.

In terms of precision retention, after 1000 hours of continuous processing, the precision loss of the FH1890L is less than 0.002mm, while the precision loss of traditional equipment can reach 0.01 - 0.02mm.

Kaibo CNC has established a global after - sales service network. No matter where the equipment is located, professional technicians can arrive at the site within 48 hours in most regions. They provide regular maintenance and inspection services, which can effectively reduce the failure rate of the equipment. For example, through regular maintenance, the failure rate of the FH1890L can be reduced from about 5% to less than 1%.

Kaibo CNC also provides comprehensive technical support and maintenance solutions. They offer online training courses for users' technical teams, enabling them to master the operation and maintenance skills of the machine more quickly. This not only improves production efficiency but also effectively controls costs.

We interviewed an engineer from Kaibo CNC, Mr. Zhang. When asked about the key to the high performance of the FH1890L, he said: "The integration of the Mitsubishi CNC system and the high - rigidity structure design are the two core factors. The CNC system provides intelligent control, and the high - rigidity structure ensures stable operation during heavy - load processing."

To help manufacturing plant equipment procurement managers and technical teams master the latest heavy - workpiece processing solutions, we strongly recommend that you get the complete technical white paper of the FH1890L large - stroke vertical machining center. You can also book a on - site demonstration to experience the excellent performance of the machine firsthand.