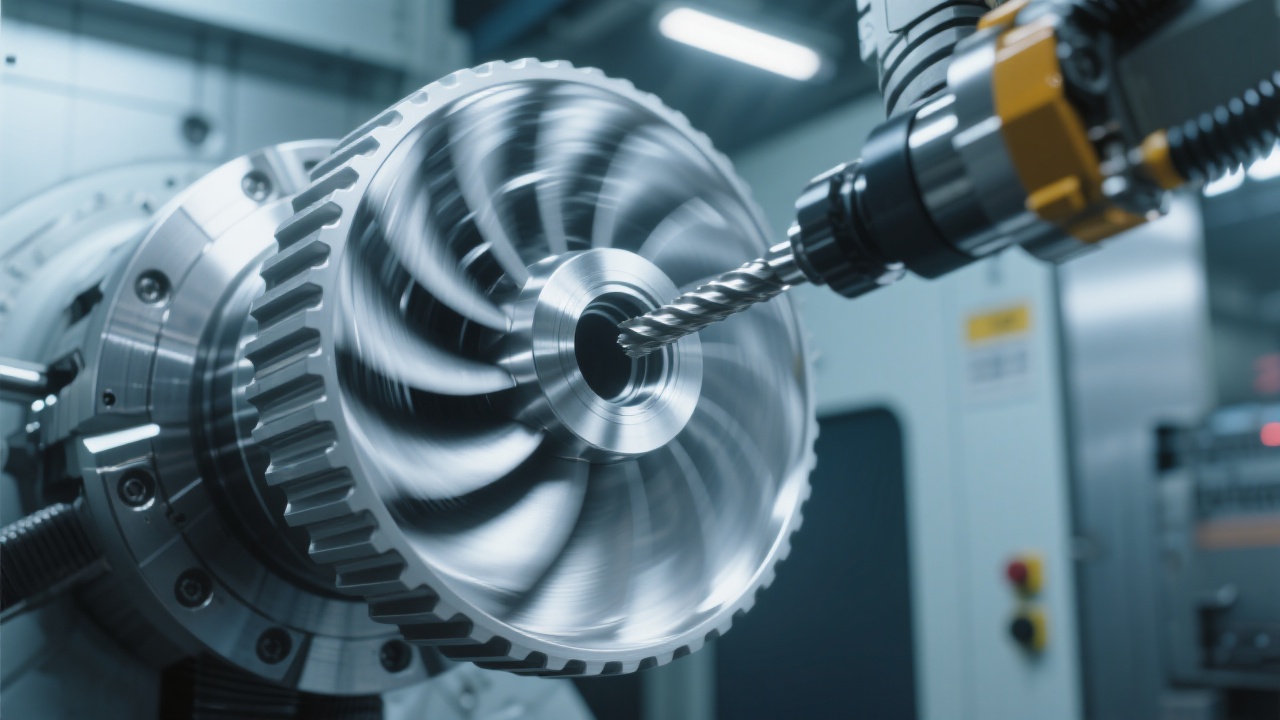

In the high-stakes world of shoe mold manufacturing, continuous and reliable operation of five-axis shoe sole mold milling machines is a decisive factor for meeting production deadlines and maintaining cost efficiency. Among the core contributors to operational uptime is the arm-type automatic tool changer (ATC) system, responsible for swift and precise tool swaps that enable multi-tool machining without manual intervention.

The arm-type tool magazine features an articulated arm mechanism that grips and transports cutting tools between the spindle and the tool storage rack. Unlike carousel or chain magazines, the arm-type system offers higher positional accuracy and faster tool exchange cycles—typically under 5 seconds per tool change—enabling manufacturers to reduce idle time and increase machining throughput by up to 15%.

The robust and compact design also accommodates longer tool holders crucial for deep cavity shoe molds and supports variable tool lengths with minimal recalibration. This flexibility is paramount for shoe mold shops facing diverse product mixes and batch sizes.

Achieving flawless tool changes necessitates synchronized execution of several automated steps:

Operators can optimize tool change parameters such as arm speed, gripper force, and dwell times through the CNC interface to minimize cycle time and prevent mechanical stress.

Downtime caused by ATC failures can cripple production flow. Based on extensive field experience, here is a practical checklist to quickly identify and address frequent issues:

| Fault | Cause | Solution |

|---|---|---|

| Tool Not Recognized | Faulty barcode/RFID reader or tag misalignment | Clean reader lens, realign or replace tags, re-scan |

| Arm Cannot Grip Tool | Gripper jaw wear or hydraulic pressure insufficient | Inspect/replace jaws, check hydraulic system pressure |

| Tool Drop During Transfer | Incorrect gripper force setting or vibration | Adjust clamp force in control system, balance machine base |

| Collision Alarm | Path obstruction or alignment offset | Clear interference, recalibrate arm coordinates |

Regular preventive maintenance and parameter audits can reduce these failures by over 40%, consequently improving mean time between failures (MTBF) to exceed 300 operational hours in standard shop environments.

One shoe mold manufacturing client reported a 12% increase in daily throughput after implementing targeted arm-type ATC parameter tuning combined with operator training on fault diagnosis. Their monthly downtime dropped from 15 hours to under 8 hours, translating into a significant rise in on-time delivery rates and contract renewals.

These measurable benefits underscore the strategic importance of investing in both technology and skills development for ATC systems.

Empower your shoe mold production with in-depth technical knowledge—Download our detailed Automatic Tool Changer Troubleshooting and Optimization Guide to minimize unexpected downtime and maximize machining efficiency.