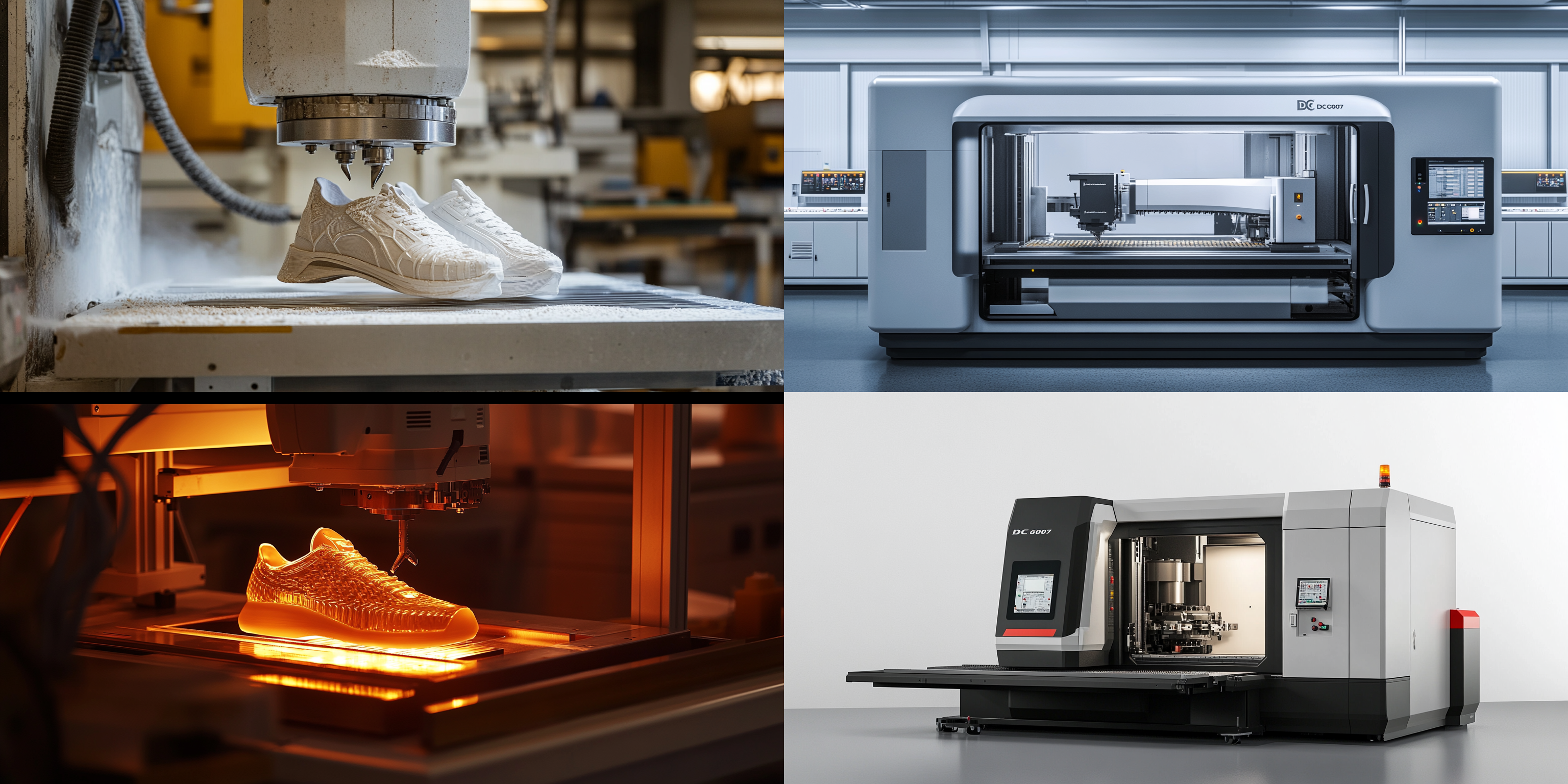

In the competitive world of shoe mold manufacturing, production downtime due to frequent tool changes remains a critical bottleneck. Studies indicate that unoptimized Automatic Tool Changer (ATC) systems can cause up to 15% production loss during frequent changeovers. As engineers at Kaibo CNC, we’ve closely examined the DC6060A five-axis shoe sole mold milling machine equipped with an articulated arm-type ATC system, and today I’d like to share practical insights on how precise calibration and tool change path optimization significantly improve operational efficiency.

Frequent tool changes interrupt machining cycles, often causing cumulative downtime that can reach several hours per week in high-volume factories. This downtime translates directly to lost output and increased labor costs. Moreover, improper calibration and route planning of tool changes amplify mechanical wear and raise the risk of tool jamming.

When comparing arm-type tool magazines with drum-type magazines in high-speed, high-load environments, the articulated arm design offers superior stability and faster tool retrieval times by leveraging multi-axis flexibility instead of relying solely on rotational mechanisms.

| Step | Description | Key Considerations |

|---|---|---|

| 1. Tool Identification | Using sensors & RFID tags to verify tool identity. | Ensure sensor accuracy above 99.5% to prevent mismatches. |

| 2. Coordinate Calibration | Matching the tool position to machine coordinates precisely. | Implement auto-calibration with real-time error compensation within ±0.02 mm. |

| 3. Path Planning | Optimizing the arm trajectory for minimal movement time. | Use algorithmic route optimization to reduce average tool change time by 20–30%. |

| 4. Execution | Physical tool release and grip with reliable pneumatic or servo controls. | Integrate sensors to detect jamming and auto-retry protocols. |

Based on our field tests, setting the ATC arm velocity parameters between 500–700 mm/s strikes a balance between speed and mechanical stress avoidance. Additionally, defining dedicated “safe zones” for tool pick and place positions minimizes collision risk.

Compensating for tool position deviation via dynamic error feedback loops not only prevents tool wear mismatch but also extends the tool life by 10-15%. We recommend seasonal recalibration intervals every 3,000 operational hours depending on workload intensity.

Issues such as tool position offset and tool change failure usually trace back to sensor misalignment or pneumatic pressure drops. Simple diagnostics like checking sensor signal integrity and air line pressure can resolve up to 85% of such faults without disassembly.

If tool jamming occurs frequently, inspect arm joint backlash and verify the tool retention force settings. Adjusting these parameters accordingly reduces downtime significantly.

Customer Case Snippet: "Since optimizing our DC6060A ATC parameters and improving calibration protocol, we’ve cut our average tool change downtime from 12 seconds to just 8 seconds, boosting daily output by over 12%. The reduced human intervention also improved overall machine utilization and operator satisfaction." – Lead Engineer, Global Shoe Manufacturer

Have you encountered tool change delays or ATC jams during shoe mold production? Share your stories below — your feedback helps us improve and tailor solutions for the industry.

Innovations in ATC configuration — from accurate tool identification to smart path planning — are pivotal in unlocking higher throughput and lean manufacturing in the shoe mold industry. Integrating these practices ensures your equipment runs at peak performance, reducing machine idle time and maintaining production continuity.