In the realm of modern manufacturing, the demand for high - precision machining of complex parts has reached an all - time high. However, traditional programming methods often fall short when dealing with the intricacies of such tasks, leading to programming pain points like low efficiency, high error rates, and sub - optimal precision. This is where five - axis technology steps in as a game - changer, offering a solution to meet the stringent requirements of high - precision manufacturing.

The five - axis programming process is a complex yet well - structured one. It starts with coordinate system setting. A proper coordinate system is the foundation for accurate programming, as it determines the position and orientation of the workpiece in the machining space. From there, we move on to tool path generation. This involves planning how the cutting tool will move across the workpiece to achieve the desired shape. One of the core functions in five - axis programming is RTCP (Rotated Tool Center Point) control. RTCP allows for the automatic adjustment of the tool's position and orientation, ensuring that the tool tip remains in the correct position even as the axes rotate. This significantly enhances the accuracy and flexibility of the machining process.

Graphite and other non - metal materials have unique characteristics. They are prone to thermal deformation and cutting force fluctuations during the machining process. To address these issues, specific programming strategies are required. For example, by carefully controlling the cutting speed, feed rate, and depth of cut, we can minimize thermal deformation. Additionally, optimizing the tool path can help to reduce cutting force fluctuations, ensuring a more stable machining process.

Let's take a look at some real - world examples, such as impellers and mold cavities. When programming for an impeller, we need to consider factors like blade shape, curvature, and the interaction between the tool and the material. By setting the right parameters and using appropriate programming techniques, we can achieve high - precision machining. Similarly, for mold cavities, programming strategies need to be tailored to the specific shape and size of the cavity, as well as the material being used. These case studies demonstrate the practical application of five - axis programming and how to set key parameters.

Mainstream CAM software like Mastercam and PowerMill are widely used in five - axis programming. However, they also come with their own set of common errors. For instance, incorrect coordinate system settings, improper tool path generation, and inaccurate interference checking can all lead to machining failures. By analyzing these common mistakes and providing avoidance guides, we can help users establish a standardized programming process. This not only improves the success rate of trial production but also enhances the first - pass forming accuracy.

A standardized programming process is crucial for improving efficiency and quality. It involves steps from initial coordinate system setting to final tool path verification. By following a standardized process, manufacturers can reduce the time required for trial production and increase the first - pass success rate. Additionally, simulation verification and interference checking are essential steps in this process. They help to identify potential problems before actual machining, ensuring the safety and stability of the manufacturing process.

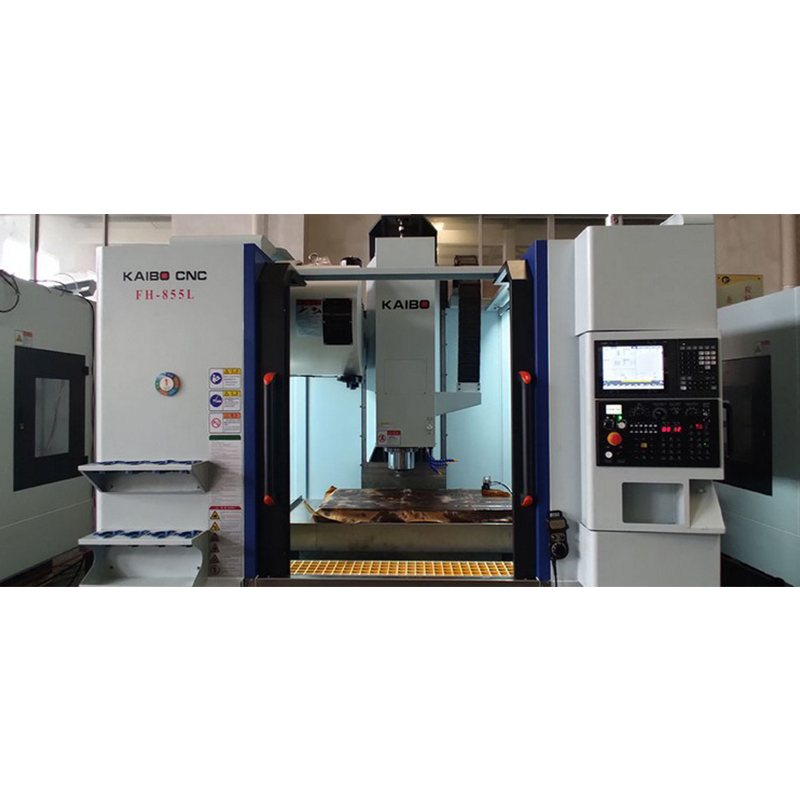

Are you ready to take your five - axis programming to the next level? The Kaibo CNC FH855L five - axis vertical machining center supports RTCP function, enabling more stable and reliable five - axis programming execution. Click here to learn more about how Kaibo CNC can help you enhance your manufacturing precision!