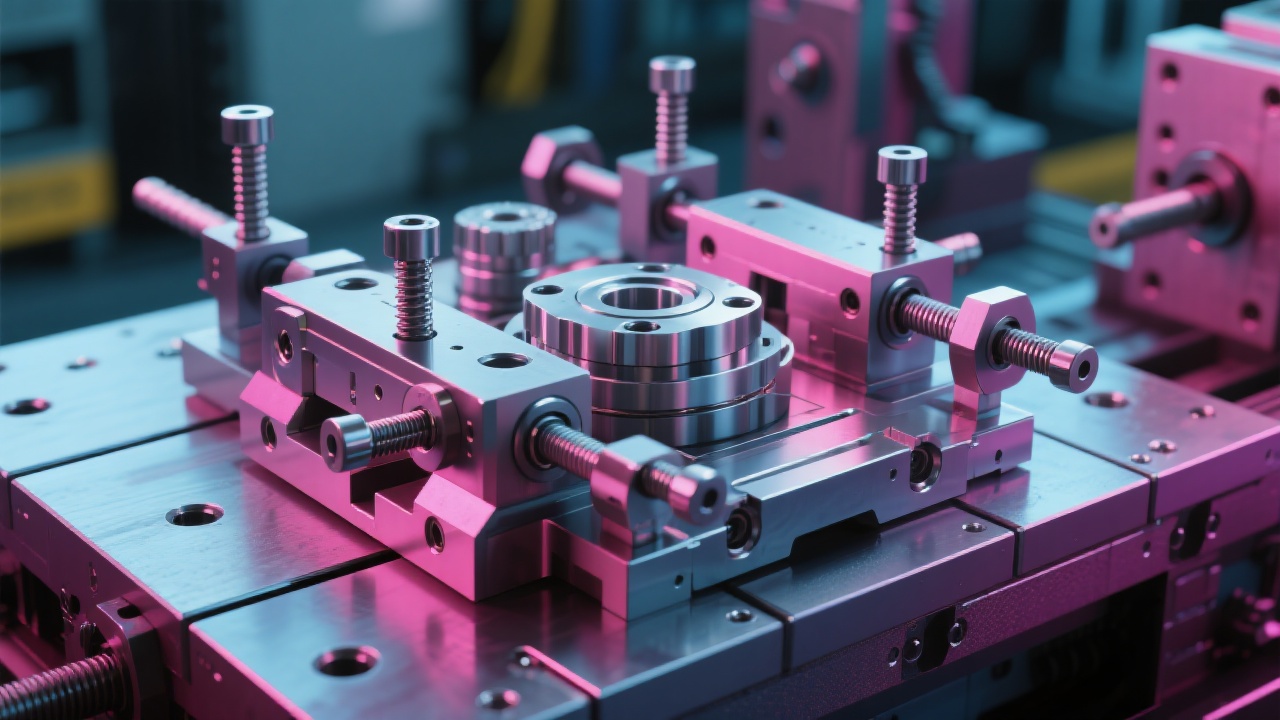

In the shoe mold manufacturing sector, the efficiency of the five-axis CNC milling machine heavily depends on the reliability of its Automatic Tool Changer (ATC) system. A failure in the ATC tool change process often leads to costly downtime, disrupted production schedules, and reduced throughput. This article delves into the core causes of ATC failures, focusing on arm-type tool magazine structures, essential parameter calibration methods, and practical troubleshooting steps to help technical professionals and workshop supervisors optimize machine uptime and tool change cycles.

Compared to carousel or chain-type tool magazines, the arm-type tool magazine offers precise positioning and faster tool retrieval times due to its dynamic gripping arm mechanism. The arm swings and locks tools, reducing mechanical wear and offering improved reliability in continuous production runs.

However, the complexity of the arm's movement introduces challenges in synchronization and coordination, requiring exact calibration of the tool arm’s position sensors and servo motor control parameters for flawless operation.

The ATC tool change process on a five-axis CNC milling machine follows a sequenced logic designed to ensure tool safety and positional accuracy:

Proper calibration of ATC parameters can significantly reduce tool change failures. Key parameters include:

| Parameter | Description | Typical Range |

|---|---|---|

| Arm Swing Angle | Defines arm rotational position to align with tool pockets | ±0.1° tolerance |

| Tool Clamp Pressure | Ensures secure hold without damaging tool shanks | 5 - 8 N·m torque |

| Sensor Sensitivity | Accuracy of tool presence detection | Adjust per manufacturer |

| Delay Timers (ms) | Wait intervals for mechanical operations | 100 - 300 ms |

Fine-tuning these parameters requires using diagnostic software and iterative testing. Even 0.05° deviation in swing angle can cause tool misalignment leading to failed clamps or tool drops.

Understanding recurring ATC failure patterns enables faster resolution:

| Failure Symptom | Root Cause | Solution |

|---|---|---|

| Tool arm does not reach tool pocket | Incorrect swing angle calibration | Recalibrate swing angle to ±0.1° accuracy |

| Tool not clamped securely | Clamp pressure below threshold or sensor malfunction | Adjust clamp torque; inspect & replace faulty sensors |

| Tool presence sensor false negative | Dirty or misaligned sensors causing improper readings | Clean sensor lenses; re-align and test sensor function |

| Frequent tool jams | Worn mechanical parts or obstructed tool paths | Lubricate joints; clear tool path obstructions; |

A reputable shoe mold manufacturer faced daily ATC failures averaging 3 per shift, causing ~45 minutes of downtime each day. Through systematic parameter recalibration focusing on arm swing angles and sensor verification, combined with operator re-training on tool loading best practices, the facility reduced ATC failures by 70% within two weeks.

Key takeaways from this case included:

Step up your shoe mold production process with our detailed operational guide packed with calibration checklists, troubleshooting charts, and maintenance tips.