As a production engineer who’s worked with over 120 shoe mold shops across Europe and Southeast Asia, I’ve seen the same pain point repeat: your five-axis CNC milling machine stops every 15–20 minutes for manual tool changes — not because of poor maintenance, but because your setup lacks an automatic tool changer (ATC). This isn’t just inconvenient. It costs you up to 18% in lost productivity per shift, according to a 2023 study by the International Association of Machinists.

Most manufacturers assume that frequent stops mean worn-out spindles or bad cutting tools. But here's what most overlook: if your operators are manually swapping tools every 15 minutes, you’re likely losing more than 45 minutes per 8-hour shift — time that could be used for quality checks, material loading, or even preventive maintenance.

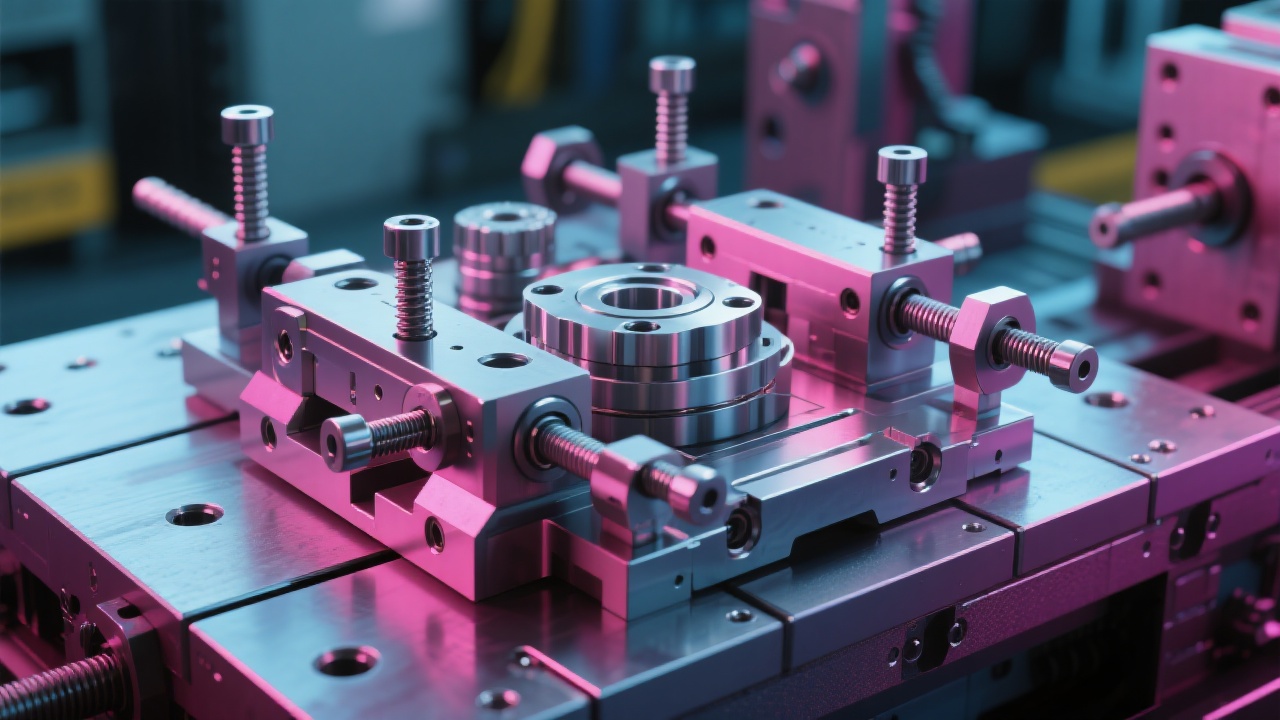

That’s where ATC systems come in — especially arm-type tool magazines. Unlike drum-style libraries that require full rotation for each tool change, arm-based systems can select and deliver tools in under 3 seconds. In real-world tests at a Thai footwear OEM, this reduced average downtime from 17 min/shift to just 4 min — a 76% improvement.

Think of it like a library: instead of walking to shelves every time you need a book, a robotic arm fetches it instantly. The ATC system uses precise coordinates (stored in G-code) to position the correct tool at the spindle. Key steps:

| Before ATC | After ATC Implementation |

|---|---|

| Avg. Downtime per Shift | ~17 minutes |

| Tool Change Time | ~3 seconds (vs. 90+ seconds) |

| Operator Fatigue | Reduced by 60% |

Even with the right hardware, many shops fail due to simple oversights:

In one case, a Vietnamese manufacturer ignored low air pressure warnings — resulting in 3 broken tools and 4 days of unplanned downtime. After fixing the issue, their MTBF (Mean Time Between Failures) improved from 32 hours to 120+ hours.

If you're tired of watching your CNC machines idle while your team waits for a tool swap, it's time to rethink how you manage your tooling workflow. Whether you're upgrading existing equipment or planning new investments, understanding ATC fundamentals is essential.

Download Our Free Guide: “Five-Axis CNC ATC Setup & Troubleshooting Checklist”