As a decision - maker in the shoe mold manufacturing enterprise, you're well - aware of the challenges in batch production. The industry now faces the need to quickly respond to various customer orders while ensuring high - quality mass production. The demand for flexibility is rising, as different shoe styles require different molds, and you need to balance between single - piece trial production and large - scale manufacturing.

The spindle speed directly affects the cutting efficiency. For shoe mold production, a spindle speed range of 8000 - 12000 RPM is often considered ideal. Higher spindle speeds can significantly reduce cutting time, especially for materials like polyurethane used in shoe molds. For example, if you're processing a complex sole mold, a high - speed spindle can complete the roughing and finishing in less time compared to a low - speed one.

Positioning accuracy is crucial for creating precise shoe molds. A positioning accuracy of ±0.005mm can ensure that the mold dimensions meet the design requirements. In shoe mold manufacturing, even a small deviation can lead to ill - fitting shoes. High - precision positioning also reduces the need for re - work, improving overall production efficiency.

In a production line, a fast tool - changing speed can save a lot of time. A tool - changing speed of less than 3 seconds can keep the machine running continuously. For multi - step shoe mold processing, quick tool changes mean less idle time between different machining operations.

A compatible control system can integrate with your existing production management software. It allows for seamless programming and operation. For example, a control system that supports G - code programming can be easily integrated into your workflow, enabling efficient production planning.

Different equipment configurations have different responses to multi - variety orders. Machines with high - end configurations can handle a wider range of mold designs with less setup time. For instance, a machine with a more advanced control system can quickly switch between different machining programs, making it more suitable for small - batch, high - variety orders.

By optimizing the programming, you can reduce the empty - stroke time of the machine. For example, some factories use software to simulate the machining process and adjust the tool path to minimize unnecessary movements. This can save up to 20% of the machining time.

Proper tool life management is essential. By analyzing the cutting force and tool wear, you can allocate the tool life reasonably. For example, a factory might use a tool for roughing until it reaches 70% of its expected life and then use it for finishing operations, maximizing the tool's utilization.

Establishing standardized machining templates can improve production efficiency. Once a template is created for a certain type of shoe mold, it can be reused for similar molds. This reduces programming time and ensures consistent quality.

To smoothly transition from trial production to mass production, you need to pay attention to key nodes. First, ensure that the machine is fully debugged during the trial production phase. Second, train your operators to be proficient in using the machine and the optimized processes. Third, continuously monitor and adjust the production process based on the actual situation.

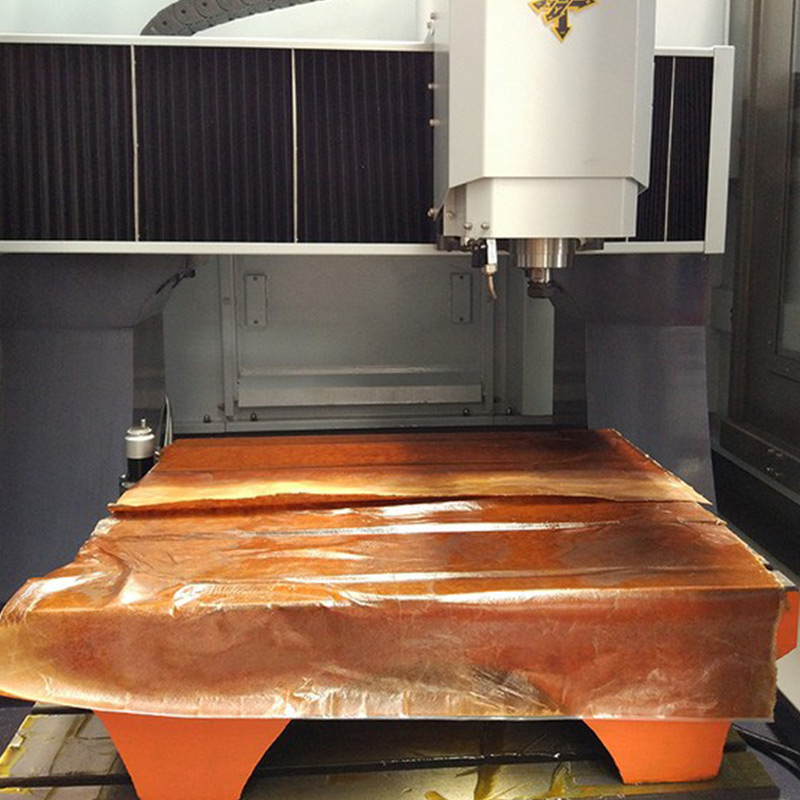

The Kaibo DC6060A five - axis sole mold milling machine is a benchmark in the industry. It combines high - speed spindle, high - precision positioning, and fast tool - changing speed. With its advanced control system, it can quickly adapt to different production requirements. Many factories have successfully improved their production efficiency after using this machine.

Don't miss the opportunity to enhance your shoe mold production efficiency. Get the Kaibo DC6060A Five - Axis Milling Machine Technical Whitepaper now to efficiently implement batch production!