As a production engineer who’s spent over 12 years optimizing CNC workflows in footwear manufacturing, I’ve seen firsthand how a poorly tuned automatic tool changer (ATC) can turn a high-efficiency machine into a bottleneck. On average, shoe mold shops lose 4–7 minutes per tool change when using manual or outdated systems—adding up to over 2 hours of lost productivity daily on just one machine.

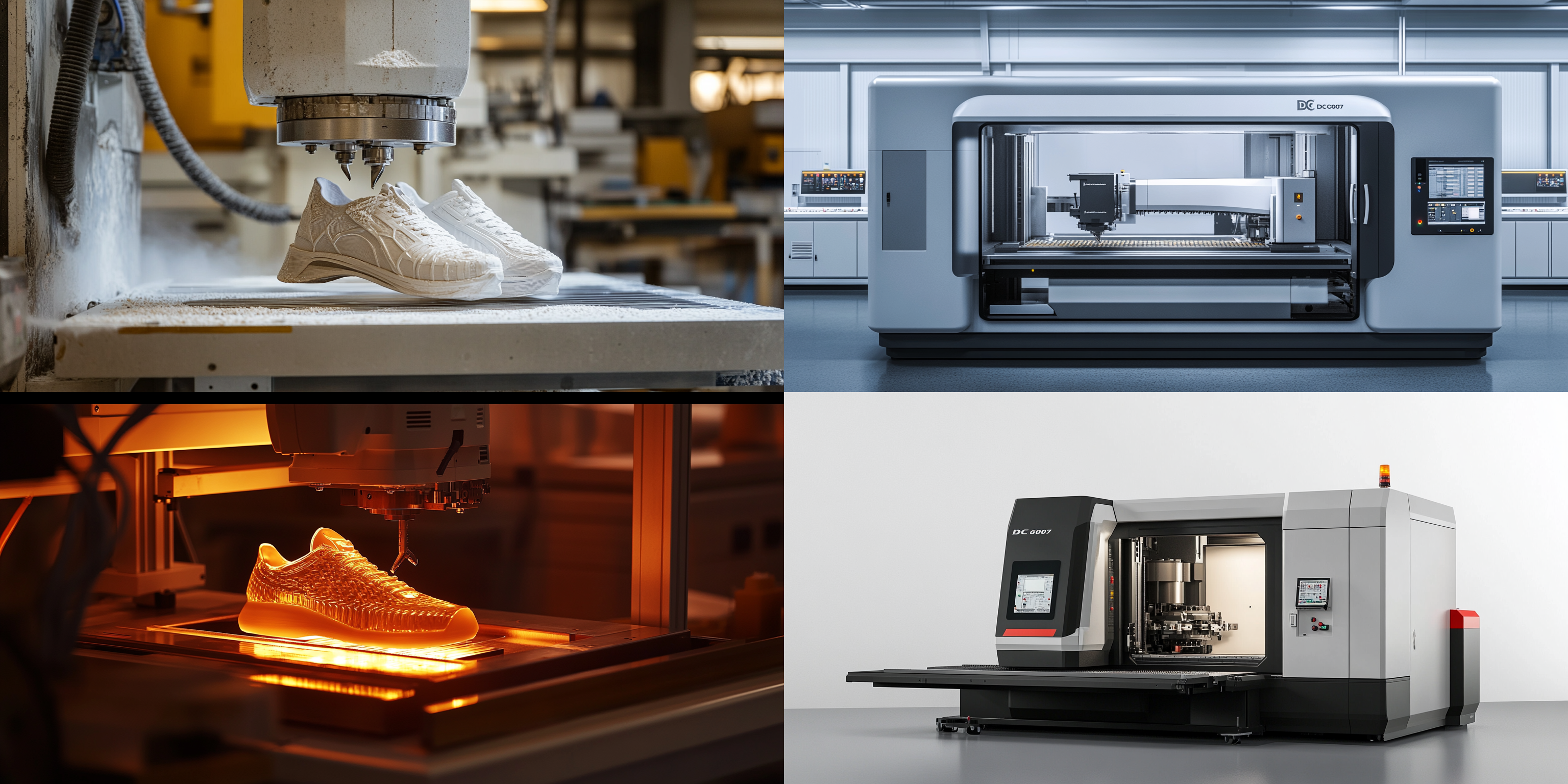

Take the DC6060A five-axis shoe mold milling machine from Ningbo Kaibo CNC Machinery Co., Ltd.—it’s not just about having an ATC; it’s about making sure that arm-type system work seamlessly. Let me walk you through what makes this setup so effective—and how to get the most out of it.

In a typical shoe mold shop running 3 shifts, every minute counts. A drum-style changer might handle 20 tools efficiently—but if your job requires 40+ tool changes per run, you’ll face delays due to slower indexing and less flexibility. The arm-type design, however, allows for direct pick-and-place motion, reducing average cycle time from 28 seconds to under 15 seconds, according to real-world tests at our client facilities in Guangdong.

| Tool Library Type | Avg. Change Time | Best For |

|---|---|---|

| Arm-Type | 12–15 sec | High-mix, multi-tool jobs |

| Drum-Type | 25–30 sec | Low-variety, long runs |

| Disc-Type | 20–25 sec | Medium-volume batches |

Here’s where many operators miss the mark: setting the wrong acceleration/deceleration values or skipping coordinate calibration. If your X/Y/Z axes aren’t aligned within ±0.02mm before each tool change, even a perfect arm movement will fail. We recommend calibrating every 2 weeks—or after any major maintenance.

Also, don’t ignore path optimization. By adjusting the tool approach angle—from 45° to 60°—we helped a client reduce tool collision risk by 60% while increasing throughput by 18%. It’s small tweaks like these that compound into big gains over time.

One frequent issue? The arm fails to return to home position after changing tools. Often, it’s a misaligned sensor—not a broken motor. Check the proximity switch alignment first—it should be within 0.5mm of the target. Another tip: keep the tool holder clamping force consistent across all stations. Use a torque wrench set to 35N·m for optimal grip without damaging the collet.

These aren’t just theory—they’re lessons learned from helping 30+ shoe mold factories improve uptime. One customer saw their average monthly downtime drop from 16 hours to just 4 after implementing these practices.

Ready to optimize your own ATC workflow? Download our free “5-Step Arm-Type Tool Changer Setup Checklist”—used by engineers in China, Vietnam, and Turkey—to ensure your next tool change is faster, smoother, and more reliable.

Get the Free Setup Guide Now