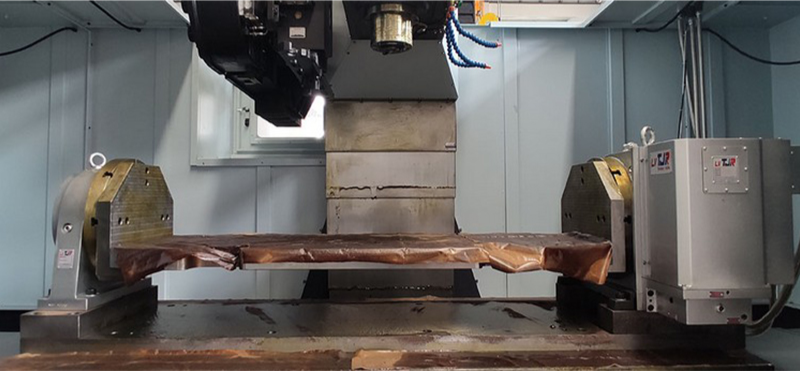

The RTCP (Rotated Tool Center Point) technology is a revolutionary advancement in the field of CNC machining. Unlike traditional three - axis machining, which has limitations in multi - face processing, RTCP technology allows for more flexible and precise control of the tool's movement. In the FH855L RTCP five - axis vertical machining center launched by Ningbo Kaibo CNC Machinery Co., Ltd., RTCP technology enables the tool to maintain a constant distance from the workpiece's surface during rotation, ensuring high - precision multi - face cutting.

Compared to traditional three - axis machining, the advantages of RTCP - enabled five - axis machining are obvious. Traditional three - axis machining often requires multiple setups and workpiece flips to process different faces, which not only increases processing time but also introduces potential errors. In contrast, the FH855L with RTCP can complete multi - face processing in a single setup, reducing the number of workpiece flips by up to 70%. This significantly improves the surface consistency of the workpiece and boosts overall processing efficiency by approximately 40%.

Graphite is a unique material with its own set of characteristics that affect the machining process. When machining graphite electrodes with the FH855L, it is crucial to optimize the cutting parameters such as feed rate, spindle speed, and cutting depth. For example, a higher spindle speed (around 12,000 - 18,000 RPM) can improve the surface finish of the graphite electrode, while a proper feed rate (about 1000 - 2000 mm/min) can ensure efficient material removal without causing excessive tool wear.

Let's take a real - world case as an example. A company was struggling with low - quality graphite electrode processing using traditional methods. After adopting the FH855L and optimizing the cutting parameters according to the material's properties, they saw a 30% improvement in surface quality and a 25% reduction in processing time. By analyzing the material's hardness, density, and thermal conductivity, users can fine - tune these parameters to achieve the best results.

For senior engineers, advanced path planning and multi - face linkage programming are key to further enhancing processing efficiency and quality control. The FH855L provides powerful programming capabilities that allow engineers to design complex machining paths. By using multi - face linkage programming, the machine can seamlessly switch between different machining operations on multiple faces, reducing idle time and improving overall productivity.

Some practical tips for path planning include minimizing tool retraction and rapid movement distances, and optimizing the order of machining operations. For instance, by planning the path in a way that the tool moves continuously from one face to another, the processing time can be reduced by up to 20%. Additionally, using simulation software to preview the machining process can help identify and correct potential issues before actual machining.

During the graphite electrode machining process, there are several common mistakes that users should avoid. One of the most common mistakes is improper tool selection. Using the wrong tool can lead to poor surface finish, excessive tool wear, and even damage to the workpiece. Another mistake is neglecting to clean the machining area regularly, which can cause graphite dust to accumulate and affect the machine's performance.

To avoid these mistakes, here are some professional tips. Always choose the right tool based on the graphite material's properties and the machining requirements. Regularly clean the machining area and the machine's components to prevent dust accumulation. Also, perform regular maintenance on the FH855L to ensure its long - term stable operation.

We encourage you to ask any questions you may have about graphite electrode five - axis machining using the FH855L RTCP five - axis vertical machining center. Whether it's about RTCP technology, cutting parameter optimization, or path planning, our team of experts will be happy to provide answers. Leave your questions in the comments section below!

The FH855L RTCP five - axis vertical machining center from Ningbo Kaibo CNC Machinery Co., Ltd. offers significant advantages in graphite electrode multi - face processing. With its advanced RTCP technology, optimized cutting parameter capabilities, and powerful programming functions, it can help users achieve higher production efficiency and better processing quality. Moreover, Kaibo CNC provides comprehensive after - sales service to ensure that your machining operations run smoothly.

Discover More about FH855L RTCP Five - Axis Vertical Machining Center