If you're working with graphite in high-precision applications—like turbine blades, molds, or EDM electrodes—you know that even a 0.02mm deviation can mean scrapped parts and lost time. That’s why mastering five-axis programming isn’t just about software skills—it’s about understanding how material behavior meets machine dynamics.

Unlike metals, graphite is brittle, anisotropic, and highly sensitive to thermal stress. A study by the International Journal of Advanced Manufacturing Technology found that up to 70% of first-pass failures in graphite machining stem from improper toolpath planning—not poor tools or machines. The key? Controlling heat buildup during cutting and ensuring consistent cutting forces across all axes.

You’ll need to adjust feed rates, spindle speeds, and stepovers based on the grain orientation of your raw block. For example, when machining a complex blade root (common in aerospace), using a 3D adaptive strategy instead of fixed-depth layers can reduce cycle time by up to 35%, while minimizing vibration-induced micro-cracks.

Thermal expansion in graphite is unpredictable—but not uncontrollable. By integrating thermal compensation into your CAM setup (especially if using RTCP—Rotational Tool Center Point), you can offset warping caused by localized heating. One manufacturer reported a 40% improvement in dimensional accuracy after implementing this technique on their mold cavity production line.

| Strategy | Impact on Thermal Deformation | Recommended Use Case |

|---|---|---|

| Variable Feed Rate Control | Reduces hot spots by 25–30% | High-aspect-ratio features |

| Toolpath Optimization (5-axis) | Improves surface finish & stability | Blade, impeller, die cavities |

| Coolant Timing Integration | Prevents localized overheating | Thin-wall structures |

And here’s where real-world results come in: companies adopting standardized templates for common graphite components report an average reduction in trial runs from 4+ to just 1.5 per project. Why? Because once you define your best practices—whether it’s for a mold insert or a custom electrode—you’re no longer guessing.

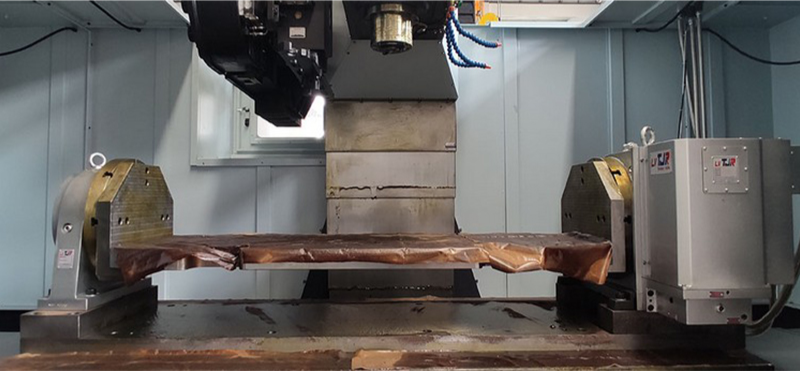

Whether you're new to five-axis machining or optimizing existing processes, the right equipment makes all the difference. KaiBo CNC FH855L RTCP 5-axis machining center supports advanced kinematics control and integrates seamlessly with modern CAM systems like Mastercam, Fusion 360, and Siemens NX—so your programs translate accurately from screen to shop floor.

Pro Tip: Always simulate your toolpaths in a virtual environment before running them live. Many shops save over $5k/month in scrap material costs by catching interference issues early—especially when working with intricate geometries like叶轮 (impellers).