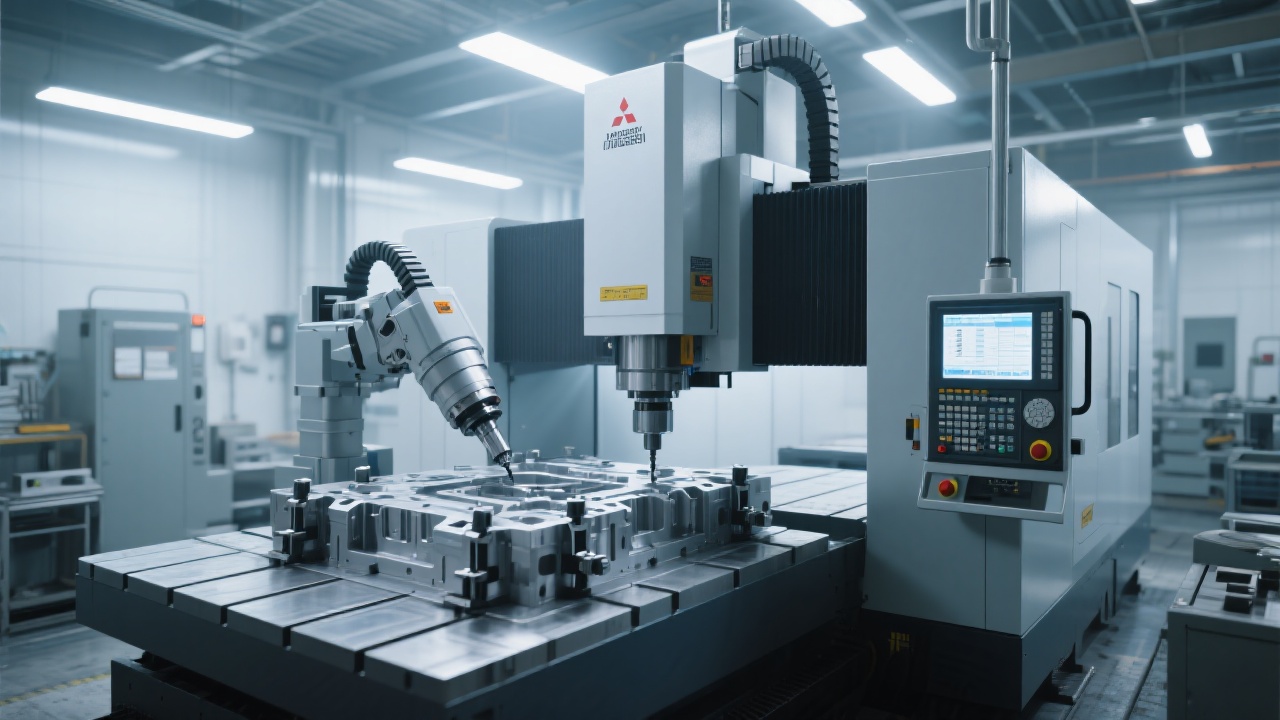

In today’s manufacturing landscape, processing heavy-duty, complex-shaped components efficiently and with high precision remains a formidable challenge. Ningbo Kaibo CNC Machinery Co., Ltd. has addressed this by pioneering the FH1890L high-cutting-rate, large-travel vertical machining center. With its advanced integration of Mitsubishi CNC control and a modular accessory design, this machine offers an innovative solution that fuses right-angle heads with universal heads to optimize complex surface milling. This article unpacks the practical techniques behind this combination, guiding manufacturing equipment decision-makers and technical teams through a proven workflow that elevates flexibility, accuracy, and productivity.

Large-scale components featuring intricate 3D geometries pose persistent issues such as difficult tool access, elevated cycle times, and the need for exceptional surface finish quality. Traditional vertical machining centers often struggle to maintain accuracy and rigidity over extended travel distances, leading to deformation and reduced tool life during heavy milling tasks. Increasingly, manufacturers require machines adaptable enough to handle variable angles without sacrificing throughput.

The FH1890L tackles these pain points with:

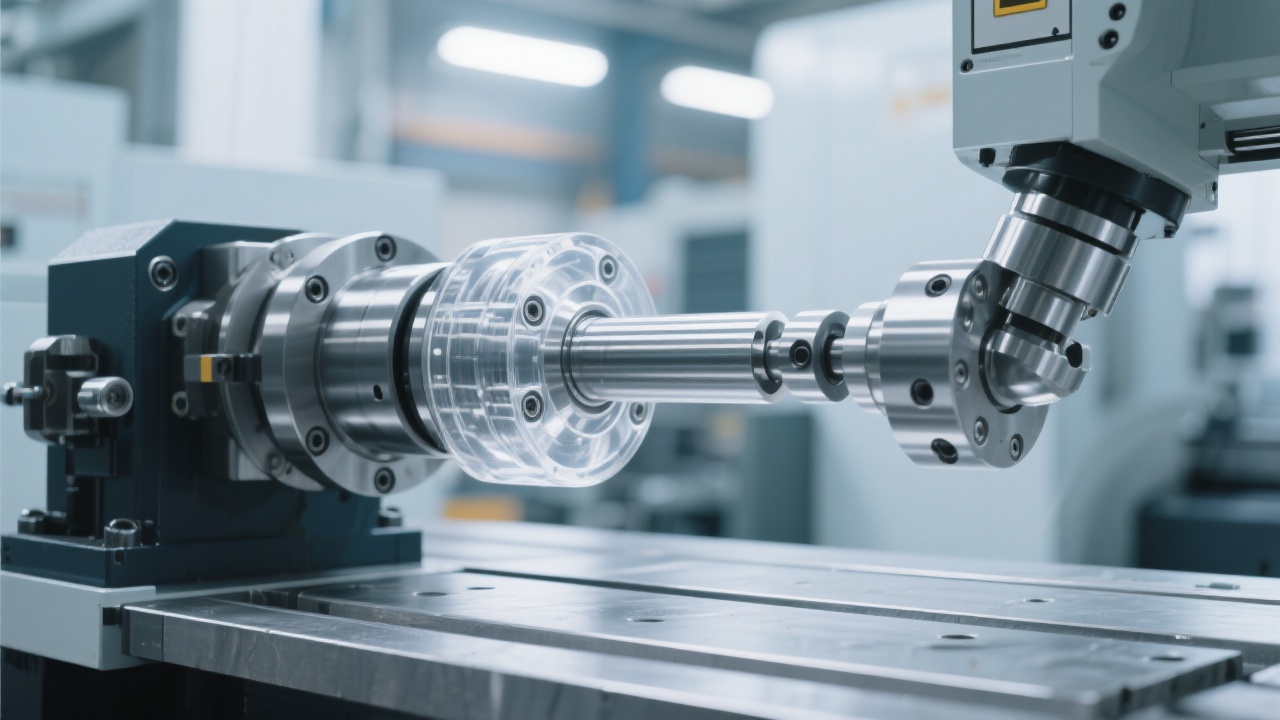

The core innovation lies in utilizing both right-angle and universal heads interchangeably within the same setup, broadening the approach vectors to complex surfaces without repositioning the workpiece. The right-angle head excels in reaching narrow, deep cavities with perpendicular tool orientation, while the universal head provides multi-axis flexibility, adapting tool angles dynamically across contours.

This complementary head combination achieves:

A leading aerospace component manufacturer implemented the FH1890L with right-angle and universal heads for turbine blade rough and finish milling. Key outcomes included:

| Performance Indicator | Before FH1890L | After FH1890L Deployment |

|---|---|---|

| Cycle Time (per blade) | 5.2 hours | 3.1 hours |

| Surface Roughness (Ra) | 1.2 µm | 0.7 µm |

| Tool Life (per tool) | 25 components | 45 components |

Designed for continuous industrial workloads, the FH1890L’s structural frame uses stress-optimized casting with vibration damping materials, maintaining machining accuracy during long cycles. The Mitsubishi CNC system provides real-time monitoring of thermal displacement and compensates accordingly, effectively stabilizing tool paths.

Modular accessories, including quick-change right-angle and universal heads, reduce maintenance downtime to under 45 minutes per head swap. The machine’s lubricating and coolant systems are engineered for high efficiency while minimizing contamination risk, further extending tool life and machine longevity.

Traditional vertical machining centers often require multiple setups and complicated manual alignments for complex parts. In contrast, the FH1890L:

These factors contribute to the FH1890L’s status as a future-proof investment for manufacturers focused on complex part fabrication with heavy workloads.

Manufacturers looking to deepen their understanding or evaluate the FH1890L firsthand can access comprehensive technical documentation including detailed machining parameters, system configuration sheets, and maintenance protocols. On-site demonstration scheduling ensures prospective clients witness the machine's capabilities applied directly to their product requirements.

Equipped with robust technology, operational insights, and real-world validation, the FH1890L stands as a leading-edge tool for manufacturers striving to excel in complex surface machining within demanding industrial sectors.