In the aerospace industry, where precision and consistency are non-negotiable, traditional machining solutions often fall short when handling large, complex components like engine casings or wing frames. Many manufacturers report cycle times that exceed 48 hours per part—and scrap rates as high as 5%—due to thermal drift, vibration-induced inaccuracies, and limited tool access.

Take one Tier-1 aerospace supplier in Ningbo, China—a client we’ve supported for over two years. Before deploying the FH1890L, they were using a conventional small-travel vertical machine with manual tool changes. Their average machining time for a titanium aircraft bracket was 52 hours, with a defect rate of 4.7%. After switching to the FH1890L equipped with a modular tooling system (including a 45° tilting head and extended spindle), their production cycle dropped to just 36 hours—a 30% reduction—and scrap rates fell below 1.2%.

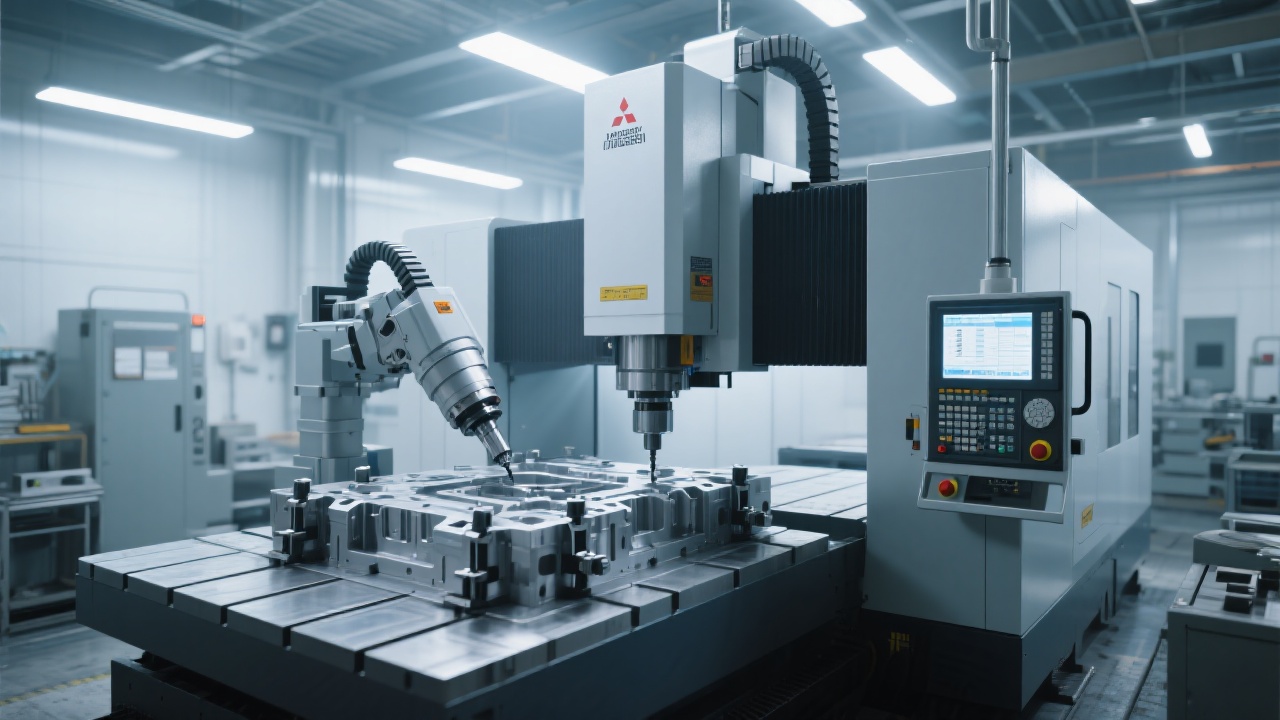

The FH1890L isn’t just another CNC machine—it’s engineered for extreme conditions. Its cast iron bed with reinforced ribbing offers superior rigidity under heavy loads, while the Mitsubishi CNC system ensures sub-micron repeatability even during long runs. The integrated thermal compensation algorithm adjusts for ambient fluctuations, maintaining accuracy across shifts—a critical feature for round-the-clock aerospace operations.

| Feature | FH1890L Advantage |

|---|---|

| Max Travel Range | X: 1800mm | Y: 900mm | Z: 900mm |

| Spindle Power | 22 kW / 10,000 RPM |

| Tool Changer Capacity | 30 tools (optional 60) |

“We used to lose up to 3 days per month due to unplanned downtime,” says Li Wei, Lead Engineer at the Ningbo plant. “Now, thanks to the built-in diagnostics and our local service team’s 4-hour response time, we’re running 98% uptime.”

With over 150+ installations worldwide—including key hubs in Germany, UAE, and the U.S.—the FH1890L is backed by a global support network. Whether it’s remote diagnostics via IoT integration or on-site technician deployment within 24 hours, customers don’t just get a machine—they gain a partner.

Already helping more than 75 aerospace manufacturers achieve annual productivity gains of 20–35%, the FH1890L stands out not only for its technical specs but for its real-world impact.

Experience firsthand how the FH1890L can streamline your heavy-part machining workflow.

Get Your Free Technical Whitepaper & Book a Live Demo Today