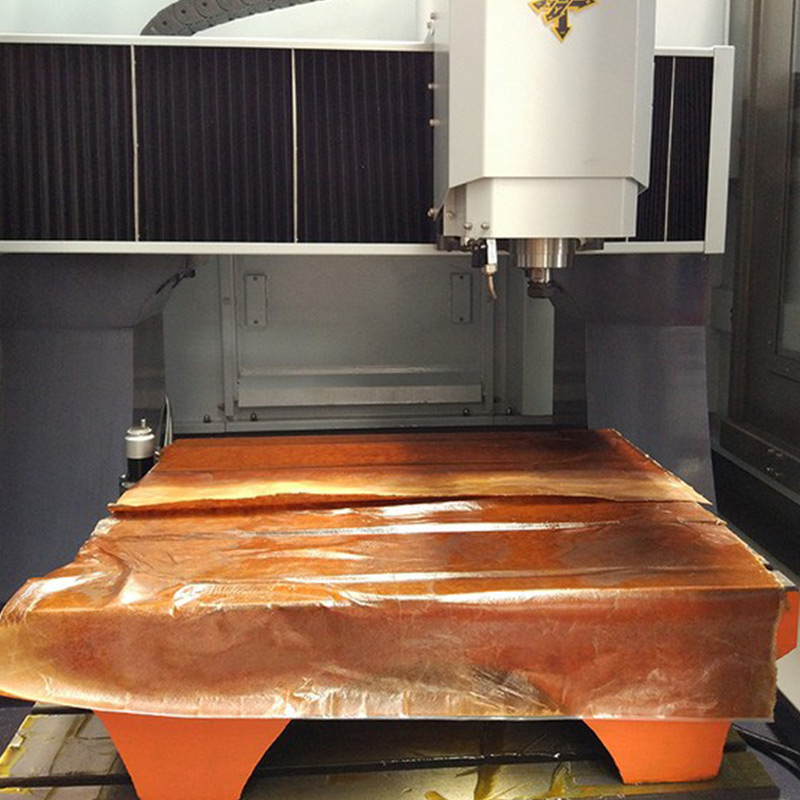

The Southeast Asian shoe manufacturing industry increasingly encounters diversified and customized product demands. This shift necessitates a manufacturing ecosystem equipped with advanced machinery capable of delivering high precision, flexibility, and efficiency. Five-axis CNC milling machines emerge as the pivotal technology enabling footwear mold producers to seamlessly transition from prototype crafting to large-scale batch production without compromising quality or turnaround times.

Southeast Asia's footwear hubs—centered in countries like Vietnam, Indonesia, and Thailand—are witnessing a surge in orders marked by smaller batch sizes and diverse design specifications. This multi-variant demand scenario challenges conventional machining setups, traditionally optimized for mass production of uniform parts. Manufacturers now require equipment that delivers rapid changeovers and consistent precision to maintain competitive lead times and product innovation.

| Performance Indicator | Recommended Range | Impact on Production |

|---|---|---|

| Spindle Speed | 12,000 – 18,000 RPM | Enables precise contouring and reduces cycle times |

| Positioning Accuracy | ±2µm or better | Ensures consistent mold geometry across batches |

| Tool Change Time | Under 5 seconds | Reduces downtime, increases throughput for multi-tool jobs |

| Control System Compatibility | Supports advanced CAD/CAM integration | Streamlines programming, facilitates rapid design iteration |

Footwear mold factories adopting five-axis CNC machines with the outlined specifications report average cycle time reductions of up to 30% on complex molds. For instance, a reputable Vietnamese manufacturer integrating spindle speeds above 15,000 RPM combined with sub-3µm positioning accuracy saw a 25% increase in order throughput, with batch sizes ranging from 10 to 200 units per SKU.

The ability to swiftly change tools and accommodate varying geometries on a single setup translates directly to cost savings and faster market delivery. These machines empower production lines to react to fluctuating order demands without requiring lengthy reconfiguration or specialized manual intervention.

Programming optimization is essential to unlocking the full potential of five-axis machines. Advanced CAM software tailored for footwear mold geometries enables path optimization that minimizes air cutting and enhances tool engagement. Factories leveraging parametric programming and simulation reduce setup errors by 40%, accelerating time-to-first-part.

Additionally, proactive tool life management — including real-time monitoring and wear analytics — significantly reduces unexpected tool failures. Standardizing machining templates across mold families also enables faster setup and consistent output quality, which is critical in multi-variant production environments.

Transitioning from single-piece prototyping to mass production demands machine stability and repeatability. Five-axis CNC systems with robust structural design and adaptive control algorithms maintain tolerances within ±2 microns over extended runs, facilitating consistent quality across thousands of units.

This industrial-grade reliability underpins Southeast Asian footwear clusters’ ability to meet multinational brand standards and rapidly respond to evolving fashion trends, ultimately enabling competitive advantage in global markets.

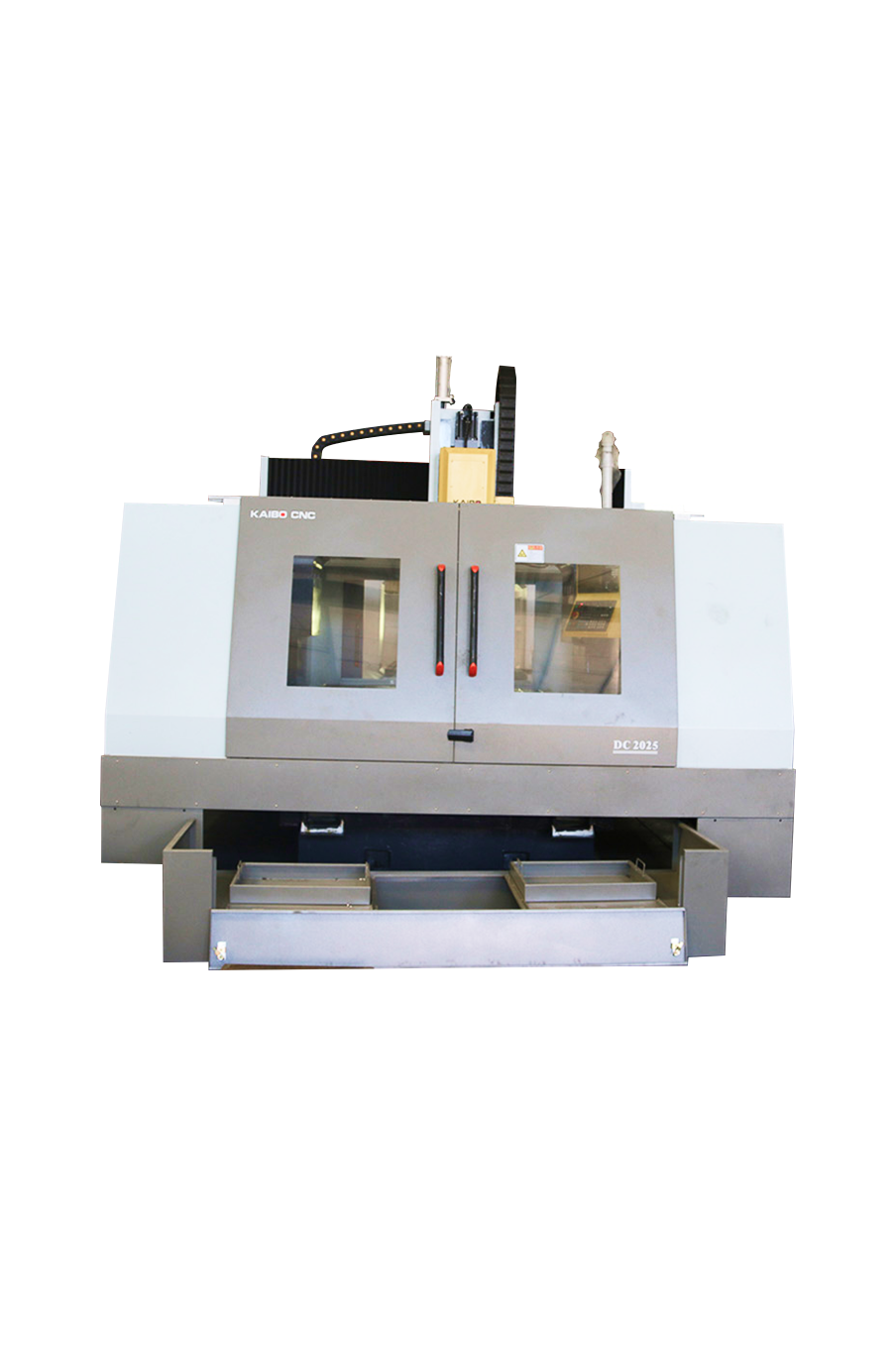

Unlock the power of precision and efficiency — Choose Ningbo Kaibo DC6060A Five-Axis Shoe Sole Mold Milling Machine and lead your footwear manufacturing into a new era of high-efficiency batch production.