For shoe mold manufacturers aiming to scale from prototypes to large-scale, multi-variant batch production, choosing the right five-axis CNC milling machine is pivotal. This guide explores critical technical considerations to optimize production efficiency, focusing on the Ningbo Kaibo DC6060A Five-Axis Shoe Sole Mold Milling Machine as a benchmark for advanced manufacturing capabilities.

| Performance Parameter | Optimal Range | Impact on Production |

|---|---|---|

| Spindle Speed | Up to 24,000 RPM | Higher speeds enable finer surface finishes and reduced cycle times |

| Positioning Accuracy | ±0.005 mm or better | Ensures dimensional consistency crucial for tight shoe mold tolerances |

| Tool Change Time | Less than 8 seconds | Minimizes downtime in multi-tool operations; vital in complex molds |

| Control System Compatibility | Supports mainstream CAD/CAM | Seamless programming and integration increase production flexibility |

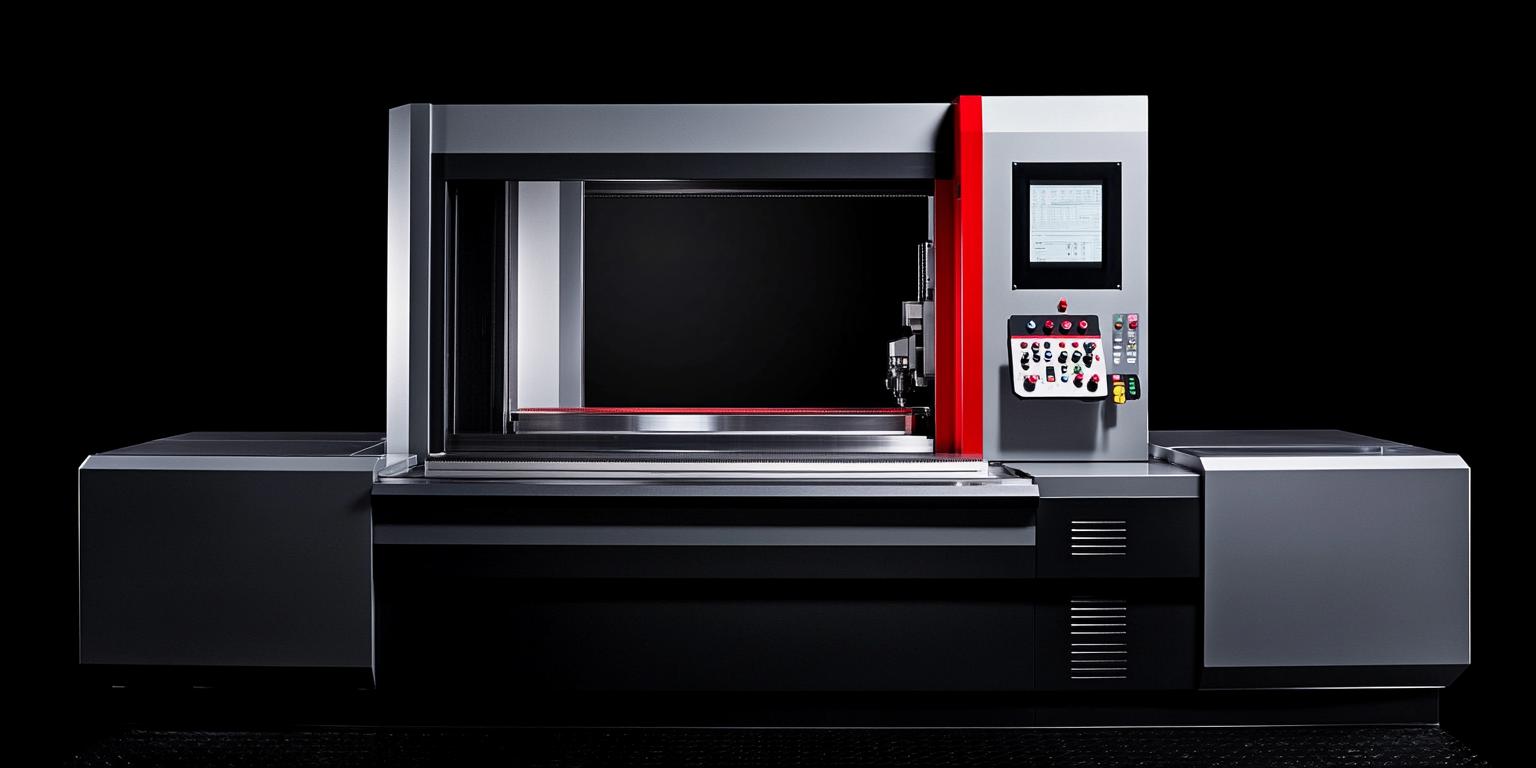

The Ningbo Kaibo DC6060A stands out by integrating a 24,000 RPM high-precision spindle, an advanced multi-axis control system compatible with industry leaders like Siemens and Fanuc, and tool changer technology achieving sub-8-second tool swaps. Such specifications empower manufacturers to maintain tight tolerances while enabling efficient multi-variant processing workflows.

Reducing non-cutting air moves is critical for batch production efficiency. By leveraging the DC6060A's flexible five-axis capabilities, factories have optimized tool paths using CAM software to generate collision-free, minimal-travel NC codes.

For example, a prominent shoe mold producer reported a 15% reduction in cycle time per mold through customized programming templates that standardize approach strategies and retract movements, while dynamically adjusting feed rates based on tool engagement.

Effective tool life management reduces production costs and prevents unplanned downtime. The DC6060A’s integrated tool life monitoring system collects real-time data on cutting parameters, wear rates, and vibration signatures, enabling predictive replacement schedules.

In practical factory environments, implementing this system yielded a 20%-30% extension in cutter lifespan by optimizing cutting conditions based on material hardness and tool load data. Operators also benefit from automated tool change alerts, minimizing risks of mold defects caused by tool degradation.

Embracing five-axis CNC milling with advanced programming and tool management allows shoe mold manufacturers to smoothly move from single-piece prototyping to complex, high-volume production with multiple mold variants. The DC6060A’s configurability supports quick product changeovers, enhanced by standardized programming modules and modular tooling systems.

Coupled with robust maintenance support and user-friendly training programs offered by Ningbo Kaibo, factories achieve sustained production reliability and competitive lead times in a demanding global footwear market.

This guide combines empirical data, hands-on optimization experience, and advanced machine specifications. Technical transparency paired with field-tested methodologies offers actionable insights for decision-makers prioritizing production agility, cost-efficiency, and quality assurance in shoe mold manufacturing.

Reliable five-axis CNC milling, exemplified by the Ningbo Kaibo DC6060A, is no longer a luxury but a necessity in competitive markets where mold precision directly impacts footwear comfort, style, and durability.

Manufacturers looking to upgrade their batch shoe mold production are advised to focus on integrated system performance—balancing speed, precision, and tool management—while leveraging advanced programming workflows to streamline machining operations.

Unlock unprecedented efficiency and flexibility in shoe mold production by discovering the Ningbo Kaibo DC6060A Five-Axis Shoe Sole Mold Milling Machine—engineered for high throughput without compromising precision. Get expert consultations and customized solutions tailored to your manufacturing goals.