In the highly competitive shoe mold manufacturing industry, the transition from single - piece trial production to large - scale production is a critical challenge for many enterprises. This article delves into the core considerations of shoe mold manufacturers when choosing CNC machining solutions for batch production, and shares effective strategies through real - world case studies.

When selecting a CNC machining solution for shoe mold batch production, manufacturers need to focus on three core dimensions: equipment performance, process compatibility, and operation and maintenance support. Equipment performance, including key indicators of five - axis CNC milling machines such as spindle speed, positioning accuracy, tool - changing speed, and control system compatibility, directly affects the production efficiency and quality. For example, a spindle speed of 12,000 - 18,000 RPM can significantly improve the cutting efficiency, while a positioning accuracy within ±0.005mm ensures the precision of shoe molds.

Process compatibility refers to how well the machining process of the equipment matches the requirements of shoe mold production. Different shoe mold products have different shapes and structures, which require the equipment to have a high degree of flexibility. The ability to respond to multi - variety orders is crucial for shoe mold manufacturers. According to a survey of 50 shoe mold factories, those with flexible production capabilities can increase their order acceptance rate by 30%.

Different configurations of five - axis CNC milling machines have different effects on the flexible production capacity of multi - variety orders. High - end configurations with advanced control systems can achieve faster response speeds and more precise processing. For instance, a machine with a high - speed tool - changing system can reduce the tool - changing time from 5 seconds to 2 seconds, thereby improving the overall production efficiency.

| Configuration Feature | Effect on Production |

|---|---|

| High - speed spindle | Increases cutting efficiency by 20 - 30% |

| Precise positioning system | Improves product precision |

| Fast tool - changing system | Reduces idle time and boosts productivity |

Based on real - world cases from front - line factories, several effective strategies can be adopted. Programming optimization can reduce the machining time. By using advanced programming software, the machining path can be optimized, and the machining time can be reduced by 15 - 20%. Tool life management is also crucial. Through scientific tool selection and usage monitoring, the tool life can be extended by 30 - 50%, which significantly reduces the production cost.

Standardized machining templates can ensure the consistency of product quality and improve the production efficiency. Once established, these templates can be quickly applied to new orders, reducing the preparation time.

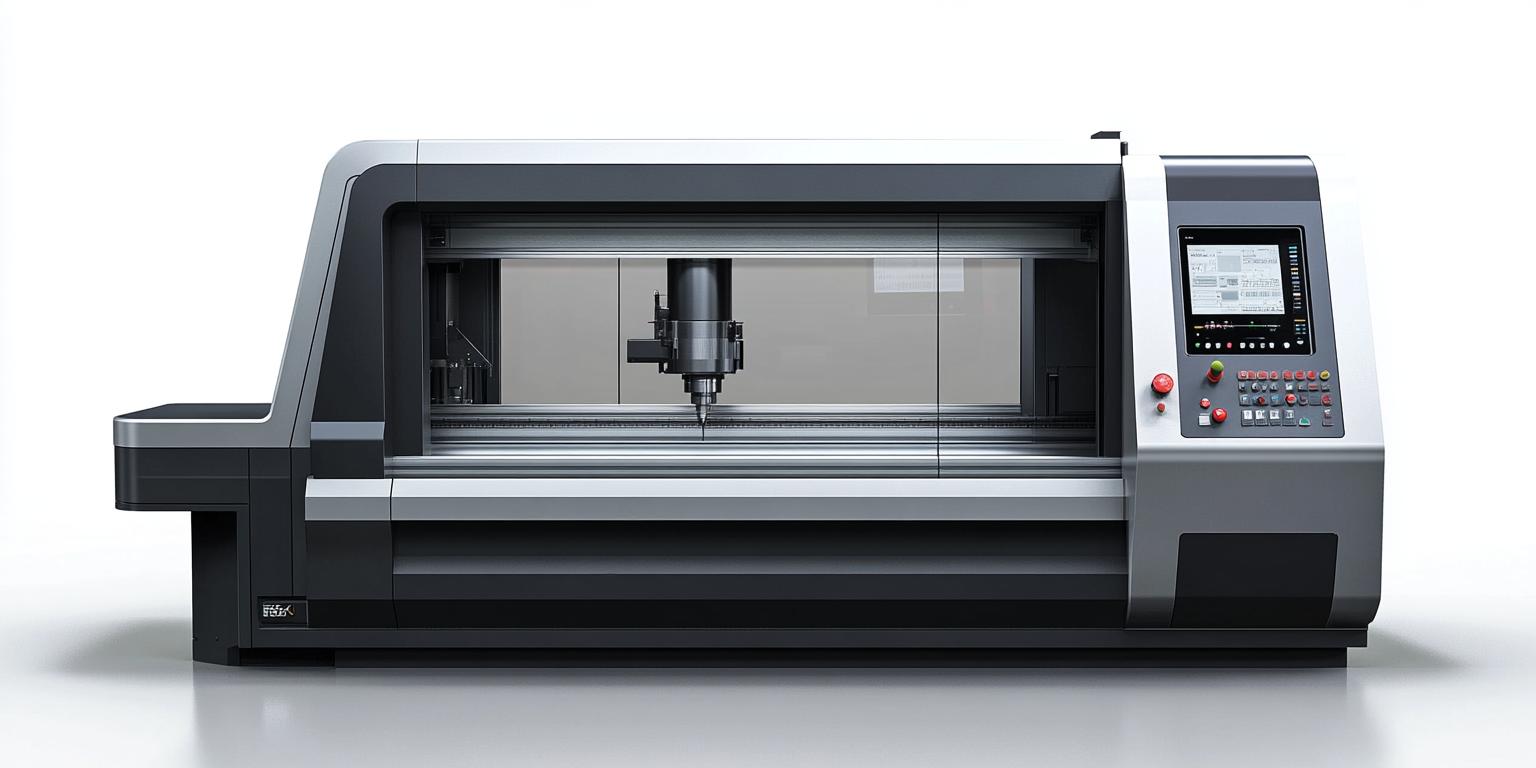

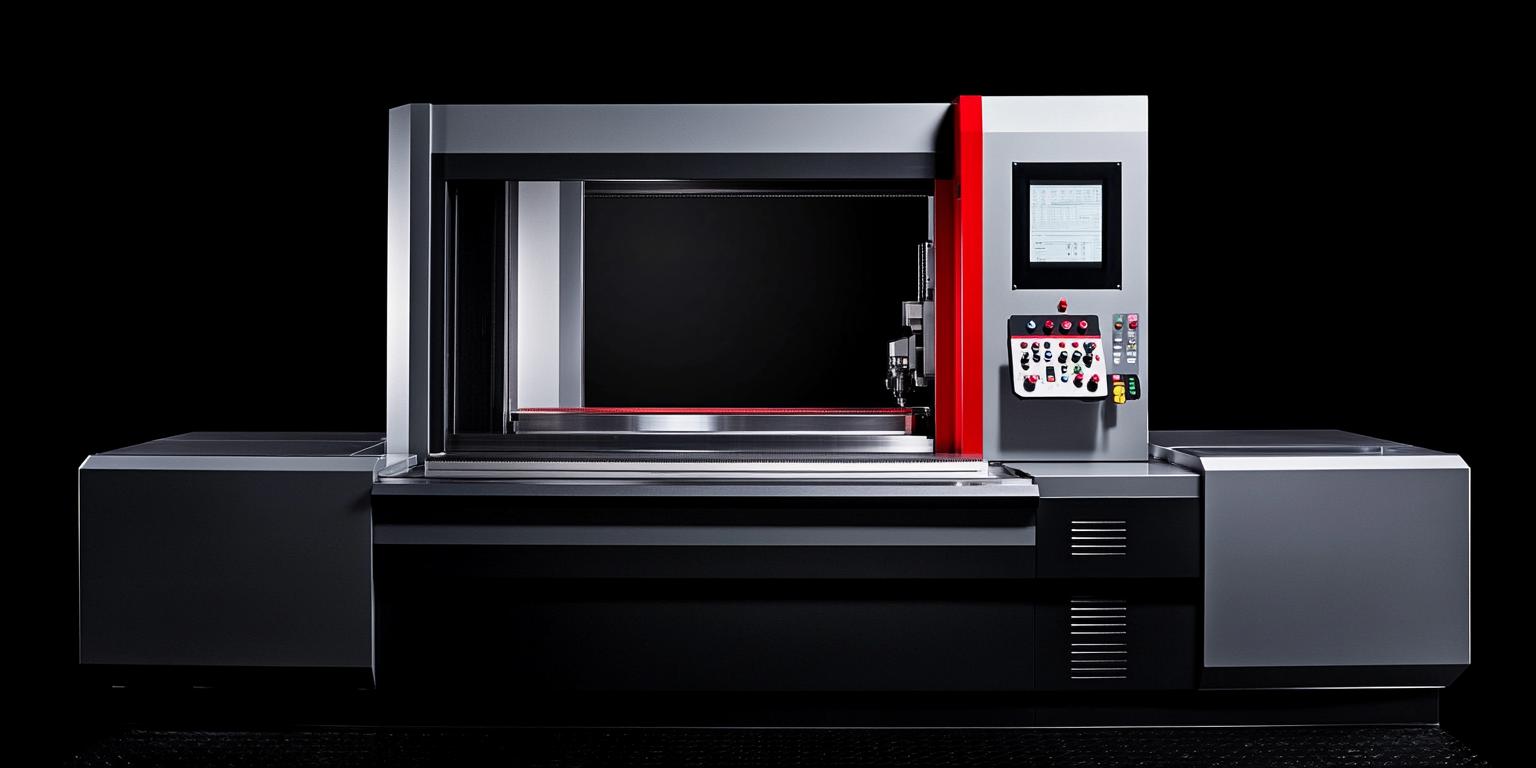

The DC6060A five - axis sole mold milling machine from Ningbo Kaibo CNC Machinery Co., Ltd. has outstanding technical advantages. It features high - speed and precise machining capabilities, which can meet the requirements of large - scale shoe mold production. Moreover, the company provides comprehensive operation and maintenance support, including regular maintenance, technical training, and rapid response to after - sales problems.

If you are a shoe mold manufacturer seeking a reliable CNC machining solution for batch production, don't miss the opportunity to explore the DC6060A five - axis sole mold milling machine. Click here to learn more and start your journey towards more efficient and competitive shoe mold production!