In today’s competitive shoe mold manufacturing industry, the ability to efficiently handle multi-variant orders is no longer a luxury—it's a necessity. Selecting the appropriate five-axis CNC milling machine significantly influences production flexibility, surface finish quality, and overall operational efficiency. This article dissects key technical parameters — including spindle speed, positioning accuracy, tool-change speed, and CNC system compatibility — to illuminate their impact on complex shoe sole mold machining.

When evaluating five-axis CNC milling equipment for batch shoe mold production, several critical specs demand close attention:

| Performance Metric | Impact on Shoe Mold Machining | Optimal Range/Benchmark |

|---|---|---|

| Spindle Speed (RPM) | Higher spindle speeds enable precision finishing on complex curved surfaces typical in shoe molds. | 12,000 – 20,000 RPM |

| Positioning Accuracy (μm) | Critical for maintaining tight tolerances on detailed mold geometries, directly influencing fit and finish. | ±2 to ±5 μm |

| Tool Change Time (sec) | Faster tool changes reduce downtimes during multi-tool machining cycles essential for complex shapes. | ≤ 8 seconds |

| CNC Control System Compatibility | Advanced control systems offer seamless integration with CAD/CAM software, enhancing programming efficiency and repeatability. | Support for latest ISO G-code standards, offline programming, and real-time diagnostics |

A five-axis CNC machine excelling in these areas enables manufacturers to flexibly respond to multi-variant shoe mold orders without compromising throughput or quality.

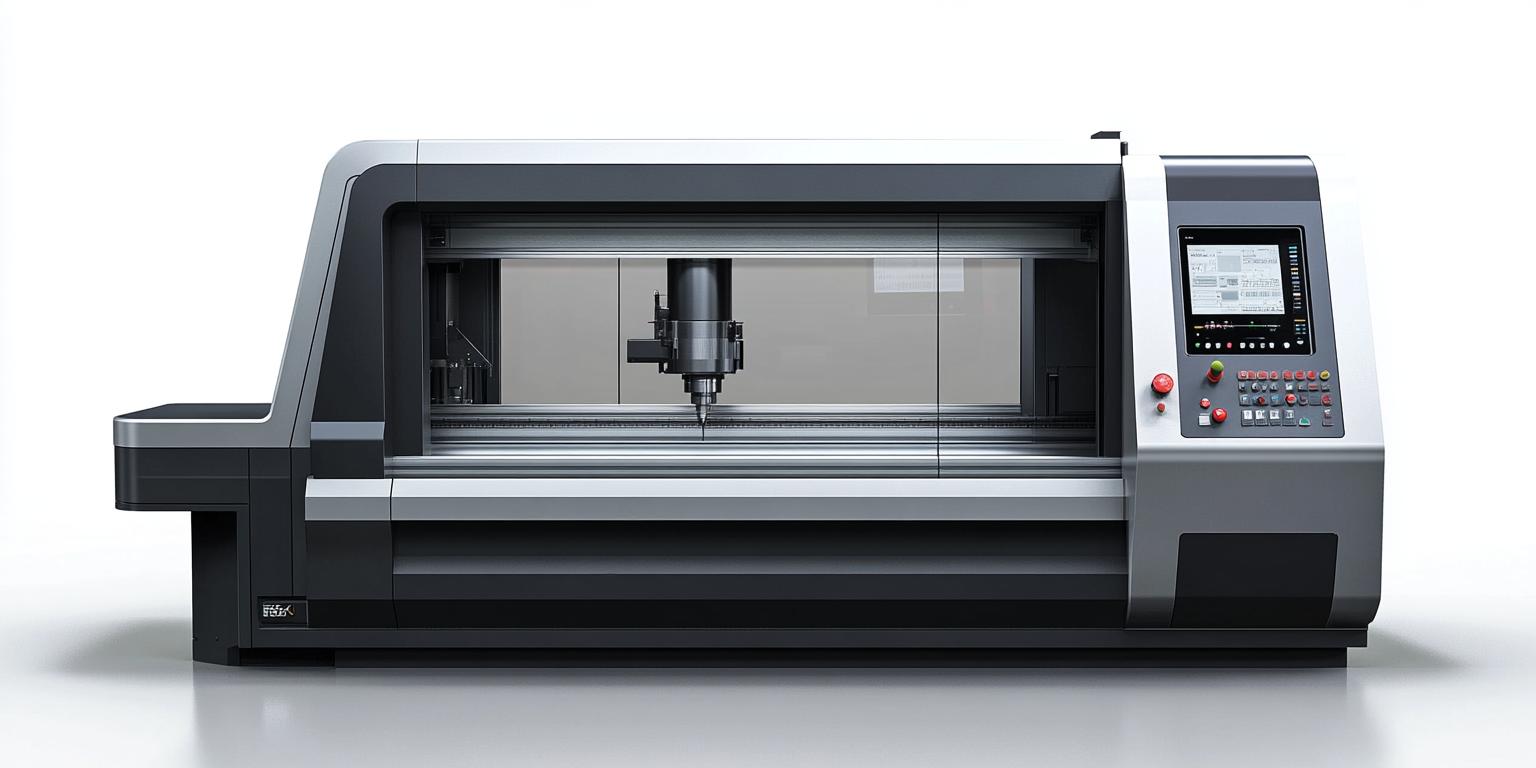

The DC6060A five-axis CNC milling machine from Ningbo Kaibo CNC Machinery Co., Ltd. exemplifies cutting-edge capabilities tailored for shoe sole mold production.

Featuring a spindle speed range up to 18,000 RPM and positioning accuracy as fine as ±3 μm, it addresses the nuanced demands of sculpting detailed shoe sole profiles. Its rapid tool changer achieves cycle times under 7 seconds, minimizing production downtime. The CNC controller supports seamless integration with major CAD/CAM platforms, facilitating rapid program adjustments for diverse mold designs.

Factory implementation reports a 15–20% boost in throughput for multi-variant orders and a reduction in scrapped parts by up to 12%, underscoring its tangible benefits in boosting production flexibility and cost-effectiveness.

Beyond hardware, companies benefit immensely by adopting refined process methodologies tailored to shoe mold production:

These approaches help manufacturers transition smoothly from prototyping single pieces to scaling batch production without loss in efficiency or quality.

Flexibility in handling diverse shoe mold orders correlates directly with reduced lead times and enhanced ability to meet bespoke client requirements—both decisive factors for gaining a competitive edge.

According to industry surveys, manufacturers implementing multi-variant-capable five-axis CNC machines have reported up to 25% faster order fulfillment and a 30% increase in client retention rates due to improved responsiveness.

Investing in advanced machine configurations and optimized operational practices enables enterprises to seize these tangible gains, empowering their growth in both domestic and export markets.