In the ever - evolving landscape of high - end manufacturing, industries such as aerospace, new energy batteries, and precision molds have witnessed a growing demand for enhanced precision and efficiency in part machining. As a result, the five - axis vertical machining center has emerged as the go - to solution for complex multi - face machining tasks. This article delves into the technical advantages of the five - axis vertical machining center over traditional three - axis equipment, especially its crucial value in processing special materials like graphite, and presents real - world case studies to illustrate how it can significantly improve the production process.

The demand for complex part machining in the aerospace and related high - end manufacturing industries has been on the rise. Traditional three - axis vertical machining centers have long been the mainstay of the manufacturing industry. However, they have limitations when it comes to complex multi - face machining. Three - axis machines can only move along the X, Y, and Z axes, which restricts their ability to access all sides of a workpiece without re - positioning. This often leads to longer setup times, increased risk of errors, and lower precision.

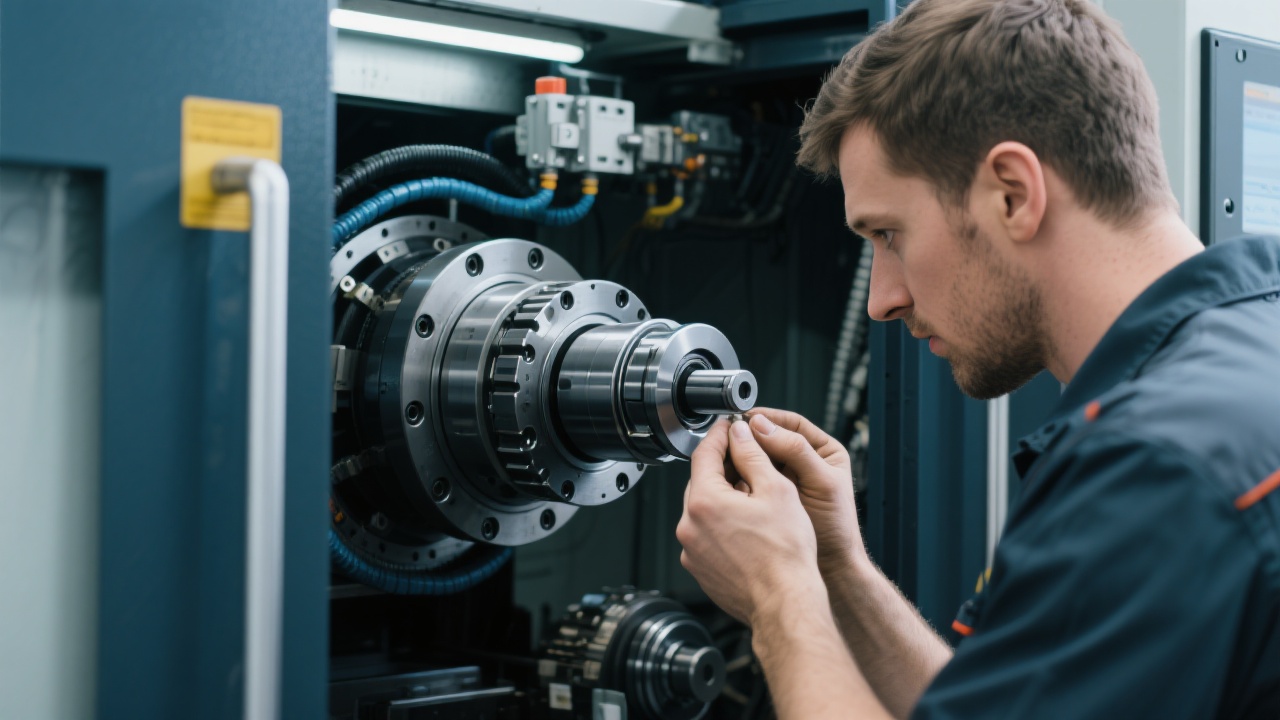

In contrast, five - axis vertical machining centers offer greater flexibility. They can move along the X, Y, and Z axes and rotate around two additional axes. This allows the cutting tool to approach the workpiece from multiple angles, reducing the need for re - positioning and enabling more complex geometries to be machined in a single setup. For example, in aerospace part machining, where components often have complex shapes and contours, a five - axis machine can complete the job with higher precision and in less time compared to a three - axis machine.

One of the key features of many modern five - axis machining centers is the integration of the RTCP (Rotated Tool Center Point) function. This function allows the machine to automatically adjust the tool path to compensate for the rotation of the tool, ensuring that the cutting point remains accurate even when the tool is tilted. This is particularly beneficial in graphite material processing.

Graphite is a challenging material to machine due to its brittleness and abrasive nature. Five - axis machining centers with RTCP function offer several advantages for graphite processing. They have high repeatable positioning accuracy, which is crucial for maintaining consistent quality in graphite parts. The machines also have strong thermal stability, which helps to prevent thermal deformation during the machining process. Additionally, they can effectively handle thin - walled structural parts, which are common in aerospace applications.

To demonstrate the real - world impact of five - axis machining centers, let's look at some customer case studies. In one aerospace manufacturing company, after switching from a three - axis to a five - axis machining center, the company saw a significant improvement in production efficiency. The machine's ability to perform complex multi - face machining in a single setup reduced the need for multiple setups and re - positioning, resulting in a 30% reduction in the overall processing cycle time. Moreover, the high precision of the five - axis machine led to a 20% increase in the product's pass rate, meaning fewer defective parts and lower production costs.

Another case involves a graphite parts manufacturer. By using a five - axis machining center with RTCP function, the company was able to reduce the tool change time by 40%. This not only saved time but also improved the overall surface finish of the graphite parts, leading to a higher - quality end product. These case studies clearly show the tangible benefits that five - axis machining centers can bring to the manufacturing process.

The five - axis vertical machining center offers significant advantages over traditional three - axis machines, especially in industries with high - precision and complex part machining requirements such as aerospace. Its ability to improve production efficiency, increase product pass rates, and handle special materials like graphite makes it an essential tool for modern manufacturing. If you're looking to upgrade your manufacturing capabilities and stay competitive in the market, consider investing in a five - axis vertical machining center. Click here to learn more about how our five - axis vertical machining centers can transform your production process.