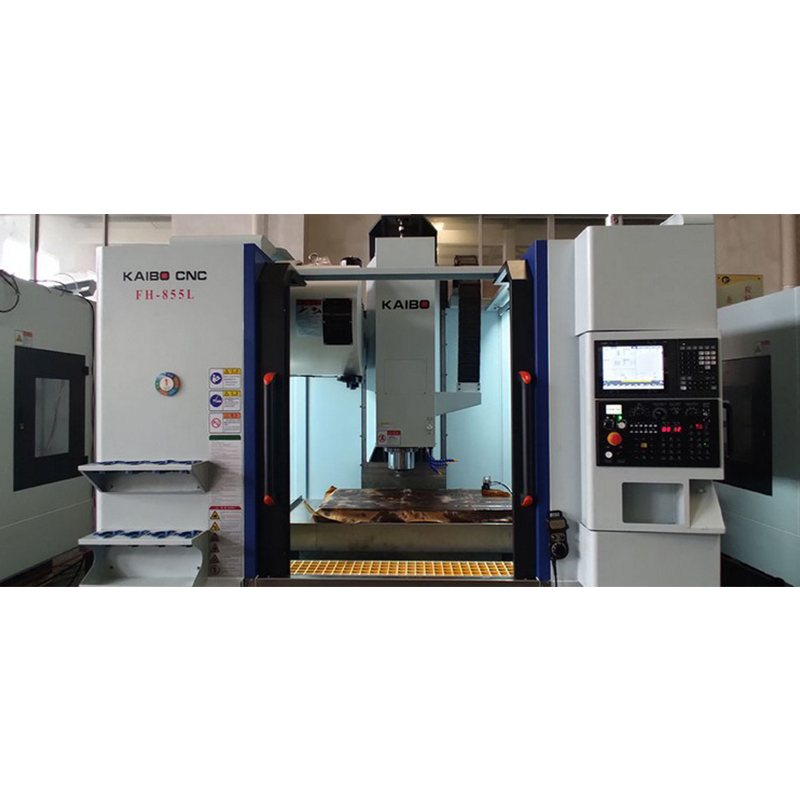

As a process engineer or manufacturing manager, you understand the challenges of machining complex graphite structural parts—multiple setup rounds, surface inconsistencies, and significant human-induced variances often hinder productivity and precision. The FH855L Five-Axis Vertical Machining Center equipped with RTCP (Rotary Tool Center Point) technology offers a paradigm shift. This article takes you through how this advanced machine optimizes cutting paths, reduces fixture changes, and enhances surface consistency, transforming your graphite machining operations into a model of stability, efficiency, and reliability.

Graphite electrodes and molds demand exceptional precision. Traditional three-axis machining often requires multiple fixtures, leading to misalignment errors and increasing the total processing time. For instance, typical workflows see over 5 fixture changes per part, with each switch contributing up to a 15% variance in surface flatness and a subsequent quality risk.

The FH855L five-axis vertical machining center drastically reduces fixture changes by enabling multi-face, multi-angle access without reclamping. This means workpiece flip-overs can be cut by approximately 60%, eliminating cumulative alignment errors and safeguarding surface consistency across complex features.

RTCP technology dynamically adjusts the tool’s center to the rotational axes, ensuring that the tool tip remains precisely on the programmed coordinate, regardless of table or spindle orientation. Unlike conventional systems, RTCP compensates automatically for tool length and angle changes during complex five-axis movements.

This precision reduces the deviation in tool paths to within ±0.005 mm on average, compared to ±0.02 mm typically seen on three-axis setups. As a result, machining accuracy and surface finish quality dramatically improve, critical for graphite parts where fine tolerances dictate electrode effectiveness and mold reliability.

Consider a graphite mold component requiring intricate undercuts and surfaces accessible only through rotational reorientation. The FH855L employs its robust RTCP-enabled five-axis motion to machine such parts in a single setup, avoiding frequent flips and recalibrations, which can extend machining by 20% or more on older machines.

Users report throughput improvements where effective cycle times shrink by up to 30%, paired with up to a 40% reduction in surface defects, thanks to consistent tool contact and minimized manual interventions.

| Parameter | Recommended Range | Effect on Efficiency & Quality |

|---|---|---|

| Spindle Speed (rpm) | 6000 - 9000 | Smooth surface finish, reduced thermal damage |

| Feed Rate (mm/min) | 1500 - 3000 | Balances cutting forces and cycle times |

| Cutting Depth (mm) | 0.05 - 0.15 | Preserves tool life, ensures dimensional accuracy |

Note: Optimum parameters depend on graphite grade and electrode geometry; adjusting within these ranges is recommended for cycle efficiency and quality balance.

A common error is neglecting the spindle-tool offset calibration before multi-face programming, which can lead to dimensional drift despite RTCP compensation. Regular calibration routines and maintaining tool holders' condition prevent such issues.

Another tip is to leverage simulation software integrated with the FH855L to visualize tool paths using RTCP prior to live runs — this helps detect collisions and optimize process flow early.

For engineers just beginning to explore five-axis machining, gradual adoption with simpler shapes helps build confidence before tackling complex multi-surface molds or electrodes.

The FH855L is backed by Kaibo CNC's extensive global service network, providing timely maintenance, software updates, and technical consulting. This ensures your machining center operates at peak reliability and speed throughout its lifecycle, reducing downtime and reinforcing production security.

What are your chief challenges when machining graphite components? Have you integrated RTCP-enabled five-axis machining in your workflow? Drop your questions and insights in the comments below—we’re here to support your journey to cutting-edge manufacturing.