As a shoe - mold manufacturer, you're well aware that the precision of complex curved surfaces in sole mold machining is a critical factor. Traditional machining methods often result in issues such as burrs and dimensional deviations. For example, in the production of high - heel soles and sports shoes with irregular patterns, the precision requirements are extremely high. Even a small deviation can lead to a significant reduction in product quality, increasing scrap rates and production costs.

The five - axis linkage technology is based on the traditional X/Y/Z axes, adding two additional rotation axes. This allows the cutting tool to reach any angle and position relative to the workpiece. For instance, when machining a complex curved surface, the X/Y/Z axes move the cutting tool in three - dimensional space, while the two rotation axes adjust the orientation of the cutting tool. This synergistic mechanism enables the cutting tool to maintain an optimal cutting angle throughout the machining process, significantly improving the surface quality and precision of the sole mold.

Let's look at the differences in terms of clamping times, surface quality, and processing cycles. In traditional three - axis machining, due to the limited movement of the cutting tool, multiple clamps are often required to machine different parts of the complex curved surface. On average, it may require 3 - 4 clamps for a single sole mold. Each clamping increases the risk of alignment errors, which can affect the overall precision of the mold. In contrast, five - axis machining can complete the entire machining process with just 1 clamp, greatly reducing the possibility of errors caused by multiple clamps.

In terms of surface quality, three - axis machining often leaves tool marks and burrs on the surface of the mold, resulting in a rough finish. The surface roughness may reach Ra 3.2 - 6.3μm. Five - axis machining, on the other hand, can achieve a much smoother surface finish, with a surface roughness as low as Ra 0.8 - 1.6μm, which is a significant improvement in the appearance and performance of the sole mold.

Regarding the processing cycle, three - axis machining usually takes 2 - 3 times longer than five - axis machining for the same sole mold. The multiple clamping and re - positioning operations in three - axis machining add to the overall processing time, while five - axis machining streamlines the process, reducing the processing cycle and increasing production efficiency.

| Machining Method | Clamping Times | Surface Roughness (Ra) | Processing Cycle |

|---|---|---|---|

| Three - Axis Machining | 3 - 4 times | 3.2 - 6.3μm | 2 - 3 times longer than five - axis |

| Five - Axis Machining | 1 time | 0.8 - 1.6μm | Shorter |

Let's take a closer look at some specific application scenarios, such as high - heel soles and sports shoes with irregular patterns. High - heel soles often have complex curves and slopes. Three - axis machining may struggle to achieve the required precision, resulting in uncomfortable wearing experiences for consumers. Five - axis machining, however, can precisely machine these complex shapes, ensuring a perfect fit between the sole and the shoe upper.

For sports shoes with irregular patterns, the three - axis machining method may not be able to create sharp and clear patterns. Five - axis machining can use the two additional rotation axes to adjust the cutting tool's orientation, creating detailed and accurate patterns on the sole, enhancing the aesthetics and functionality of the sports shoes.

Many of our customers have experienced significant efficiency improvements after switching from three - axis to five - axis machining. For example, a customer who used to produce only 50 - 60 sole molds per week with three - axis machining was able to increase the production volume to 100 - 120 sole molds per week with five - axis machining. The scrap rate also decreased from 8% to 2%, greatly improving the overall production efficiency and product quality.

If you're still hesitant about switching to five - axis machining, we recommend starting with a single - model trial production. This allows you to evaluate the actual performance of five - axis machining in a real - world scenario. Once you've confirmed the advantages, you can gradually expand the scope of application to batch production.

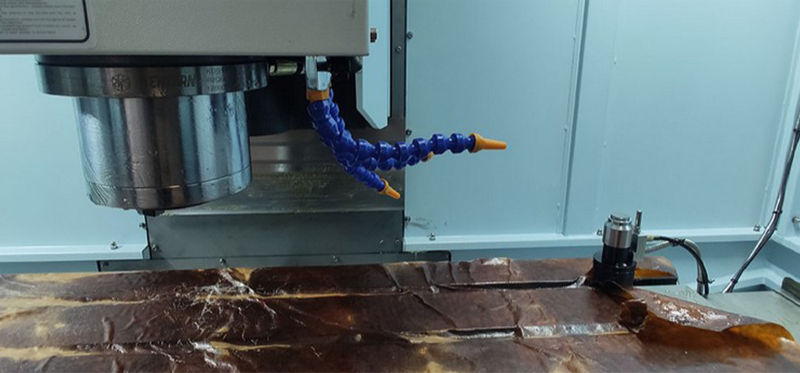

The Kaibo DC6060A five - axis sole mold milling machine is precisely designed to meet these requirements. It combines advanced five - axis linkage technology with high - precision components, providing a reliable solution for shoe - mold manufacturers. If you're interested in learning more about how five - axis machining can transform your production process, click here to explore further. Do you have any experiences or questions about five - axis machining in sole mold manufacturing? Share them in the comments below!